Comprehensive Guide to Custom Synchronizer Services

- Share

- publisher

- PairGears

- Issue Time

- Jun 18,2025

Summary

Professional guide on custom synchronizer services for vehicles and machinery—design, manufacturing, applications, and quality control.

1. Introduction

1.1 What Is a Synchronizer?

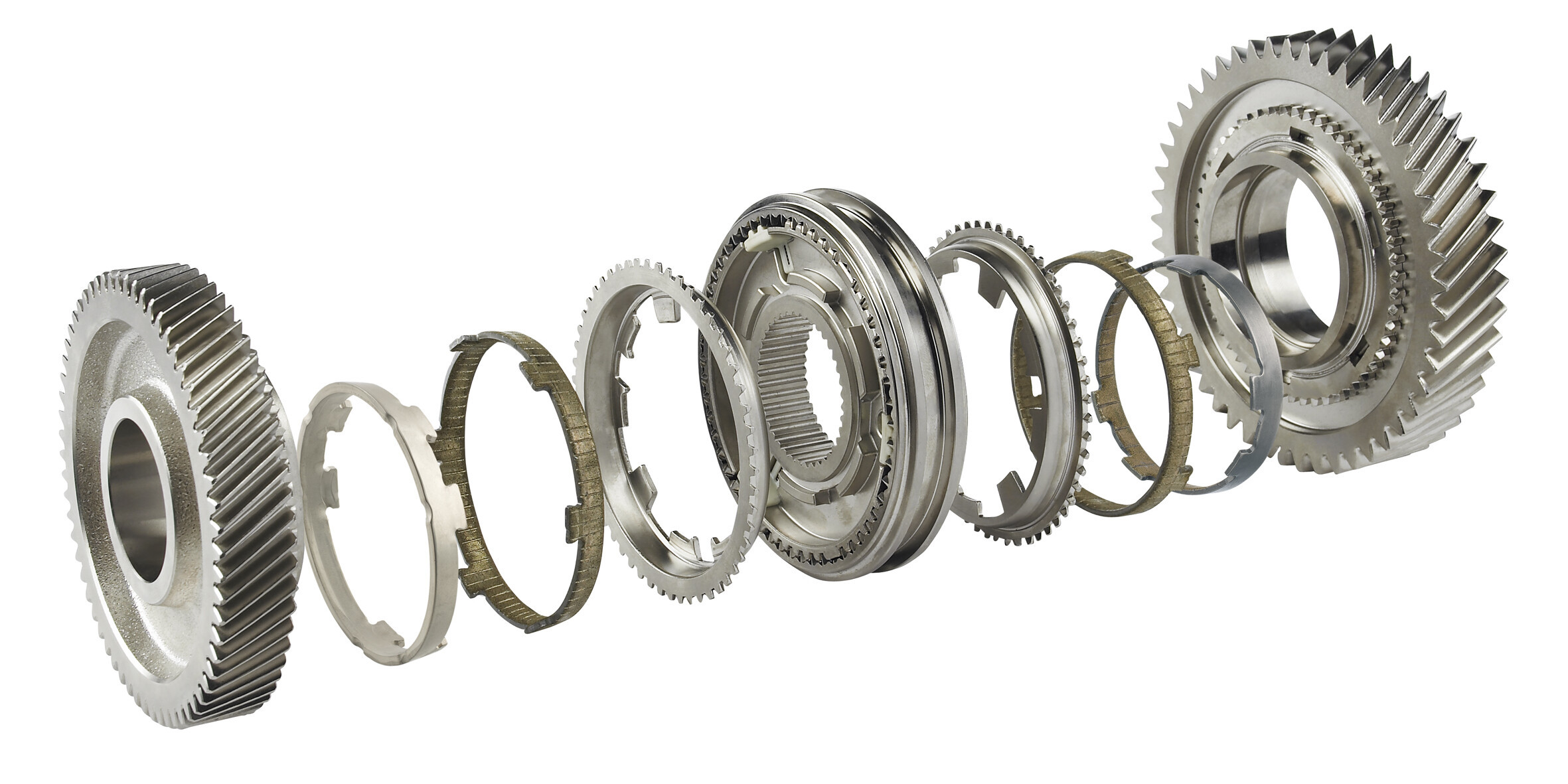

A synchronizer is a key component within a manual transmission system, enabling smooth engagement between gears by equalizing their rotational speeds. It ensures smoother gear shifting and extends transmission lifespan.

1.2 Why Choose Custom Synchronizers?

Custom synchronizers are engineered to meet specific torque, load, and performance requirements. Whether you operate heavy machinery or performance vehicles, tailored synchronizer solutions improve reliability and efficiency.

2. Advantages of Synchronizers

2.1 Enhanced Gear Engagement

Synchronizers allow seamless and noise-free gear transitions, reducing mechanical stress and driver fatigue.

2.2 Improved Longevity

High-quality synchronizers help minimize gear wear, significantly extending the life of the entire transmission system.

2.3 Adaptability to Complex Systems

Modern powertrains require advanced components. Custom synchronizers ensure compatibility with multi-speed gearboxes and high-performance systems.

3. Our Custom Services at PairGears

3.1 Tailored Engineering Solutions

PairGears offers custom synchronizer design services, taking into account input from OEMs and aftermarket clients. Our engineers consider your specific torque loads, operating environments, and shaft dimensions.

3.2 Material Options

• Case-hardened alloy steels

• Stainless steel for corrosion resistance

• Bronze and brass-based friction rings

3.3 Specifications and Parameters

We design based on:

• Outer/Inner diameter

• Number of teeth

• Cone angle

• Friction lining material

3.4 Surface Treatments

• Nitriding for surface hardening

• Phosphate coating for corrosion resistance

• Precision grinding and lapping for smooth engagement

3.5 Advanced Manufacturing Capabilities

• CNC multi-axis machining

• Heat treatment under controlled atmospheres

• High-precision gear cutting and broaching

3.6 Rapid Prototyping and Delivery

We deliver prototypes in as fast as 7-10 working days. Our lean manufacturing ensures timely batch production without sacrificing quality.

Explore our gear capabilities at PairGears.

4. Technical Details

4.1 Key Design Parameters

Designing a custom synchronizer involves:

• Cone torque calculation

• Material friction coefficient

• Synchronizing time estimation

4.2 Material Science

Different base metals affect wear rate, performance under thermal stress, and compatibility with transmission oils.

4.3 Production Workflow

4.3.1 Material selection and cutting

4.3.2 Precision machining

4.3.3 Surface finishing

4.3.4 Assembly and quality checks

4.4 Friction Surface Optimization

Modern synchronizers often use carbon-fiber, molybdenum, or sintered metallic coatings to ensure consistency and durability.

5. Quality Control

5.1 Quality Assurance Protocols

• Cone angle tolerance check

• Friction surface consistency inspection

• Metallurgical testing

5.2 Inline Monitoring

Every step of production is monitored via digital traceability systems.

5.3 Certifications

We are ISO 9001:2015 certified and align with IATF standards. Certificates available upon request.

6. Applications

6.1 Automotive

Used in commercial trucks, performance cars, and vintage vehicle restorations.

6.2 Industrial Machinery

Heavy-load gearboxes in cranes, drilling systems, and conveyors.

6.3 Agricultural Equipment

Tractor and combine transmissions.

6.4 Specialty Vehicles

Defense and off-road vehicles requiring high-durability gear synchronizers.

7. Real Use Cases

• Agricultural OEM: Custom synchronizers helped reduce shifting errors by 43%.

• Motorsport Transmission Builder: Enhanced carbon-lined synchronizers improved shift time by 0.2 seconds per gear.

8. FAQ

Q1: What's the minimum order quantity?

A1: MOQ varies by design complexity. Typical MOQ starts at 50 units.

Q2: Can you reverse engineer from samples?

A2: Yes, we offer full reverse engineering services.

Q3: Do you supply globally?

A3: We ship to North America, South America, Europe, and Asia.

Q4: Can I get a sample?

A4: Yes, prototyping is part of our service.

Q5: How long does it take?

A5: Typically 20–30 days for production orders, 15–20 for samples.

9. Start Your Project

9.1 Contact us via Contact Page

9.1.1 Submit drawing or requirements

9.1.2 Technical consultation & quotation

9.1.3 Confirm specs and initiate production

9.1.4 Delivery and aftersales support

9.2 Contact

Email: Jessica@pairgears.com

Website: www.pairgears.com

10. Conclusion

Choosing a custom synchronizer is essential for applications requiring high precision and endurance. At PairGears, we combine engineering expertise, precision manufacturing, and flexible service to deliver high-performance synchronizer solutions for a wide range of industries.Contact us today to get started on your next precision synchronizer project.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.