Comprehensive Guide to Custom Sprocket Services

- Share

- publisher

- PairGears

- Issue Time

- May 31,2025

Summary

Explore our in-depth guide to custom sprocket services. Learn about materials, design, applications, and why PairGears is your ideal sprocket supplier.

1. Introduction

1.1 What Are Sprockets and Why Custom Matters

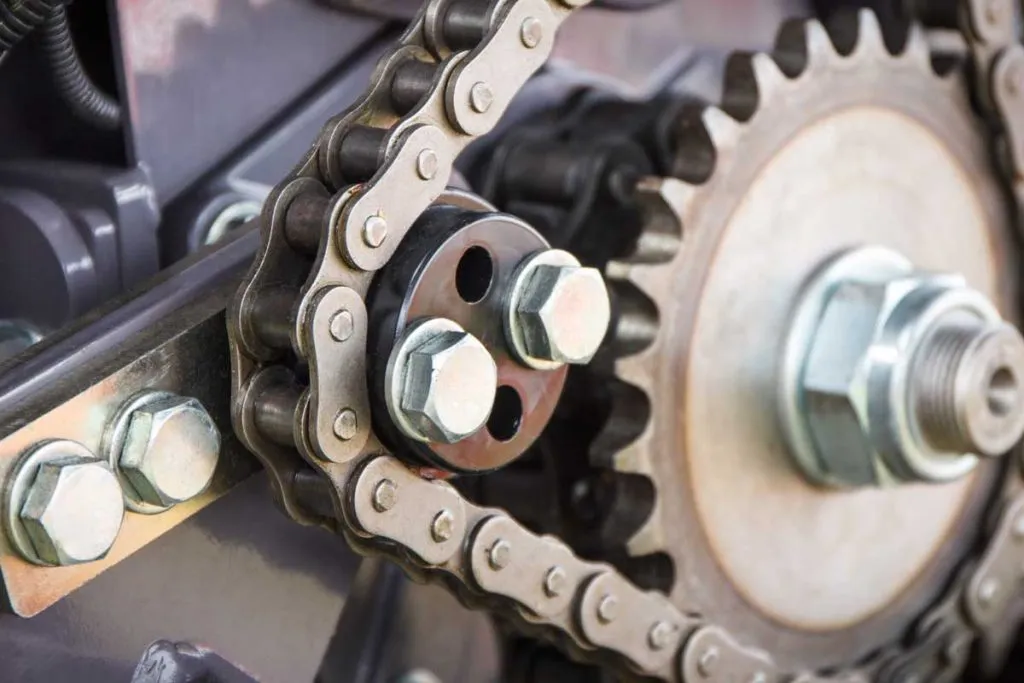

Sprockets are toothed wheels used to engage chains or belts in machinery. Unlike generic options, custom sprockets allow for precision in pitch, bore, material, and teeth count, which directly impacts system performance, efficiency, and longevity.

1.2 Why Choose Custom Sprockets?

Custom sprockets meet specific operational conditions such as torque load, shaft alignment, or harsh environmental settings. PairGears offers full-spectrum custom sprocket solutions optimized for various industries.

2. Advantages of Custom Sprockets

2.1 Enhanced Power Transmission Efficiency

Tailored sprockets reduce chain wear and increase torque transfer due to optimized tooth profile and spacing.

2.2 Reduced Noise and Vibration

Precision-manufactured sprockets improve chain alignment, minimizing vibration and operating noise.

2.3 Increased Lifespan and Load Capacity

Custom sprockets designed with appropriate materials and surface treatments perform better under heavy or high-speed loads.

3. Our Custom Sprocket Services

3.1 Bespoke Design Solutions

Our engineers analyze operational conditions to design sprockets with precise specifications—pitch, bore size, hub type, and keyways.

3.2 Material Options

3.2.1 Carbon Steel (AISI 1045, 4140)

3.2.2 Stainless Steel (304, 316)

3.2.3 Hardened Steel

3.2.4 Aluminum and Brass

3.3 Size & Specification Flexibility

We support custom module sizes, number of teeth, and chain compatibility (ANSI, ISO, DIN standards).

3.4 Surface Treatments

3.4.1 Black oxide coating

3.4.2 Zinc plating

3.4.3 Nitriding

3.4.4 Phosphate coating

3.5 State-of-the-Art Manufacturing

3.5.1 CNC milling and turning for dimensional accuracy

3.5.2 Gear hobbing and broaching

3.5.3 Heat treatment for increased hardness and durability

3.6 Fast Turnaround & Global Delivery

Efficient workflow and inventory enable us to deliver custom sprockets globally with short lead times.

4.1 Key Design Parameters

Understanding: pitch diameter, tooth profile, pressure angle, chain pitch, and center distance—all affect performance and wear.

4.2 Material Science

For example, 4140 steel offers a balance of toughness and fatigue strength, making it ideal for industrial sprockets.

4.3 Manufacturing Process Overview

From blank preparation to final grinding:

4.3.1 Forging or CNC-cut blanks

4.3.2 Hobbing teeth profiles

4.3.3 Keyway and bore machining

4.3.4 Heat treatment

4.3.5 Final inspection

4.4 Role of Surface Finishing

Proper finishing enhances corrosion resistance and improves sprocket-chain interaction.

5.1 Rigorous Inspection Standards

We follow ISO 9001:2015 quality management and perform:

5.1.1 Runout tests

5.1.2 Hardness and metallurgical checks

5.1.3 Surface finish measurements

5.2 Real-Time Process Monitoring

Our manufacturing line uses real-time quality monitoring systems for dimensional and structural checks.

5.3 Certifications

We support industry standards including:

• ISO

• CE

• ROHS (upon request)

6. Applications of Custom Sprockets

6.1 Automotive

Used in timing mechanisms, transfer cases, and hybrid system drives.

6.2 Industrial Machinery

For conveying, packaging, and automation systems.

6.3 Agriculture

Heavy-duty sprockets for combines, balers, and seeders.

6.4 Energy

Oil rig equipment, wind turbines, and other high-load environments.

6.5 Food & Beverage

Stainless sprockets in conveyors meet hygiene standards.

7. Real-World Case Studies

7.1 Agricultural Machinery:

PairGears delivered nitrided stainless sprockets for a Brazilian harvester manufacturer.

7.2 Robotics:

Custom mini-sprockets for European automation startup.

7.3 Heavy-Duty Conveyors:

Hardened sprockets for a German cement plant.

Q1: What’s the minimum order quantity for custom sprockets?

A1: Minimums vary, but low-volume runs are possible. Contact our sales team.

Q2: What’s the lead time for orders?

A2: Typically 7-20 business days depending on complexity and order size.

Q3: Can you supply prototypes or samples?

A3: Yes, prototype and batch sample services are available.

Q4: Do you offer design assistance?

A4: Absolutely, our engineering team provides full support throughout the design phase.

9. Getting Started

9.1 Quick Onboarding Process

• Submit design specs or sample

• Receive quote within 24h

• Approve drawing and confirm order

• Production and delivery

9.2 Contact Us

Email: Jessica@pairgears.com

Website: www.pairgears.com

10. Conclusion

Custom sprockets offer high performance, durability, and compatibility across industries. At PairGears, we specialize in reliable, tailored sprocket manufacturing. Contact us today for expert guidance and a free consultation.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.