Sustainable Manufacturing at PairGears: Our Commitment to Green Production

- Share

- publisher

- pairgears

- Issue Time

- Feb 15,2025

Summary

PairGears: Sustainable gear manufacturing with green practices, eco-materials, energy efficiency, waste reduction, and high-quality products for a greener future.

Introduction

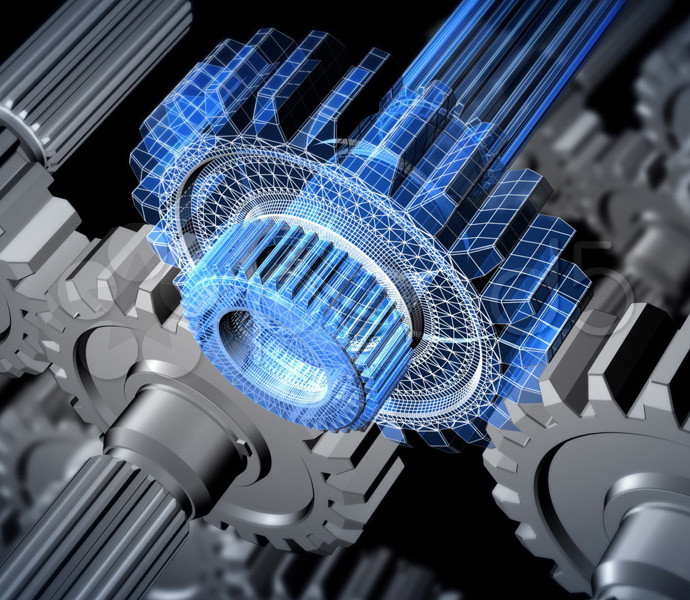

At PairGears, we believe in driving innovation and performance, not only in our gear products but also in the way we approach manufacturing. Sustainability is at the core of our operations, and we are committed to reducing our environmental impact through green production practices. As a leading manufacturer of high-quality gears for industries ranging from agriculture to automotive, we recognize our responsibility to protect the planet while providing the best products to our customers.

A Green Manufacturing Vision

PairGears’ commitment to sustainability is reflected in our dedication to reducing carbon emissions, optimizing energy consumption, and minimizing waste. By integrating eco-friendly practices into our production processes, we aim to contribute to a greener future while maintaining the high standards of excellence our customers have come to expect. Our gear manufacturing processes are designed to ensure that each step, from raw material sourcing to final product delivery, minimizes environmental impact without compromising on quality.

Eco-friendly Materials and Energy-Efficient Production

One of the key pillars of our green production approach is the use of eco-friendly materials. At PairGears, we prioritize materials that not only meet the highest industry standards for performance and durability but also support sustainability. For example, we are increasingly using recycled metals and materials with low environmental impact in our gears. These materials help reduce the carbon footprint associated with gear production and ensure that we are doing our part to reduce waste.

In addition to sustainable material selection, we have implemented energy-efficient technologies in our production facilities. Our commitment to energy conservation includes using advanced machinery that consumes less power and optimizing our production processes to reduce unnecessary energy usage. By investing in energy-efficient equipment, we reduce our operational costs and minimize our environmental footprint.

Waste Reduction and Recycling Initiatives

Waste reduction is a key focus at PairGears. We take proactive steps to minimize waste generation during the manufacturing process. Our facilities are equipped with state-of-the-art waste management systems that ensure the recycling of scrap materials, reducing the amount of waste sent to landfills. Additionally, we are committed to reducing packaging waste by using recyclable materials for our gear products, ensuring that our packaging materials are both functional and environmentally friendly.

Our Future Goals: Continuous Improvement in Sustainability

At PairGears, sustainability is not a one-time effort—it’s a continuous journey. We are committed to continuously improving our manufacturing processes to become even more eco-friendly. Our goal is to achieve further reductions in energy consumption, carbon emissions, and waste generation. We are exploring new ways to innovate, such as incorporating renewable energy sources into our production lines and enhancing the sustainability of our supply chain.

Our customers can trust that when they choose PairGears for their gear needs, they are not only selecting top-tier products but are also supporting a brand that is actively working to protect the environment and promote sustainable practices.

Contact Us