Why Precision Gears Matter in Everyday Machines

- Share

- publisher

- Jessica

- Issue Time

- Sep 18,2025

Summary

Discover how precision gears power tractors, trucks, and EVs in daily life, and why choosing the right gear supplier matters.

Introduction

We focus on providing precision gears suitable for agriculture, trucks, construction machinery, and electric vehicles. As we excel in custom gear production, every gear we manufacture is reliable, durable and fully meets the customers' requirements. But have you ever stopped to think - why are gears so important for the machines we use every day? Let's analyze it together.

1. Gears in Agriculture: Powering the Fields

Think about tractors plowing the soil or harvesters picking crops—gears are the ones moving all that torque and power around. Without good-quality gears, those heavy farm machines would really struggle to work in the tough conditions out in the fields.

Take modern tractors, for example—they usually use spur gears in their transmissions to keep torque steady when plowing or pulling something. The straight teeth on these gears don’t just make them easier to make; they also move power really efficiently. That’s a big deal when you’ve got heavy work to get done in the fields. Farmers depend on these precision gears to run for hours without breaking down. And if you pick a reliable gear supplier, those farm machines can keep going season after season, with barely any time stuck not working.

2. Gears in Trucks: Carrying Heavy Loads

When a truck is carrying dozens of tons of stuff down the highway, its transmission needs precision gears to balance speed and strength. Straight cut gears work great when there’s a lot of weight to carry, while helical gears keep things quieter and less bumpy.

For heavy-duty trucks, straight cut gear transmissions are often used when the going gets tough—like climbing steep hills or hauling super heavy cargo. These gears have a simple shape that means less friction, so more of the engine’s power goes straight to the wheels. They’re noisier than helical gears, but their strength and efficiency make them the best pick for trucks that need to perform well or carry heavy things. At PairGears, we make both straight cut and helical precision gears—we design them to balance how long they last and how comfortable the ride is, depending on what the customer needs.

3. Gears in Construction: Handling Extreme Conditions

Excavators, bulldozers, and cranes use heavy-duty industrial gears that can stand up to dust, bumps, and running non-stop. These gears are made from hardened alloys so they last as long as possible.

Let’s talk about cranes—their lifting systems often use bevel gears to change the direction of torque between shafts. This design lets them lift heavy things straight up while keeping the gear system small. On construction sites, where there’s dust everywhere, things bumping into each other, and super heavy loads, only precision gears made from hardened materials can stay reliable. And with custom gear manufacturing, we can tweak those bevel gears to fit specific lifting capacities and safety rules.

4. Gears in Electric Vehicles: Quiet and Efficient Motion

An electric motor can immediately provide you with torque, but it is the precise gears inside an electric vehicle that ensure smooth and quiet power transmission. This is why custom gear are so important here - electric vehicles require special gear designs to work efficiently without generating too much noise.

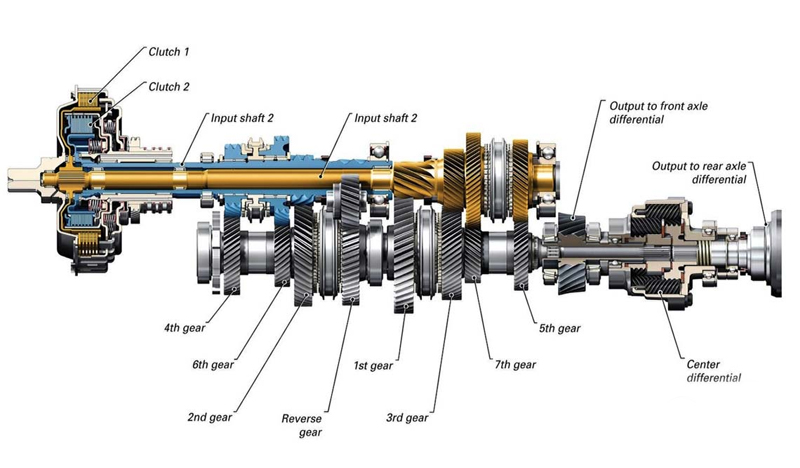

In electric vehicles, differential gears do a key job: when the car turns, they split torque between the left and right wheels. Unlike regular gas-powered cars, EVs have torque instantly, which puts more stress on the drivetrain. Precision-made differential gears make sure turning is smooth, reduce tire wear, and make the car handle better. These days, a lot of top EV makers work with custom gear manufacturers to make quieter, more efficient differentials that fit electric drivetrains perfectly.

5. Why Gear Suppliers Matter

Not all suppliers are equal. Reliable gear suppliers like PairGears offer:

(1)Strict material and heat-treatment standards.

(2)Advanced testing and inspection processes.

(3)Tailor-made custom gear manufacturing solutions.

Conclusion

Whether it’s the tractor in the fields, the truck on the road, or the EV in your driveway, precision gears are at the heart of performance and reliability.

At PairGears, we combine decades of expertise with modern engineering to deliver custom gear solutions for global industries.

Contact Us today to learn how our gears can power your business.