Why OEMs Choose PairGears for Low-Volume Custom Runs

- Share

- publisher

- Jessica

- Issue Time

- Aug 14,2025

Summary

Low-volume, low-risk: PairGears offers flexible MOQs, <30-day first-article, and full custom gear manufacturing to help OEMs validate, scale, and save.

1. OEM Low-Volume Reality: Why Tight Isn’t Always Right

If you lead an OEM program, you know the pain points: suppliers set high MOQs, push out lead times, hesitate on engineering changes, and pass along risk premiums for short runs. Yet early design phases—prototypes, DV/PV builds, pilot lines, low-rate initial production (LRIP), and localized service parts—demand flexible supply.

PairGears was built to close this gap. As a precision gear manufacturer specializing in custom gear manufacturing for OEMs, we engineered our flow for low-volume, high-mix environments—without sacrificing quality or traceability.

What this means for you:

• Faster learn cycles. Sub-30-day first articles accelerate design validation and PPAP-like documentation.

• Lower working capital. MOQs from 1 piece and refundable tooling reduce cash locked in inventory.

• Less operational risk. An integrated, in-house process reduces hand-offs, rework, and schedule slips.

• Right-sized precision. We match process capability to your functional tolerances—tight where it matters, efficient where it doesn’t.

2. Flexible Commercials Designed for Prototypes, Pilots, and Service

2.1 MOQ that Actually Matches Engineering Reality

• MOQ = 1. Whether you need prototype gears, one-off replacement parts, or engineering trials, we support it.

2.2 Lead Time that Enables Iteration

• ≤ 30 days for First Article after tooling confirmation (process-appropriate).

• Instant RFQ turnaround once drawings are confirmed, so you can lock cost and timing early.

2.3 Tooling Cost that Doesn’t Stall Programs

• Tooling prepayment, then rebated/credited after designated production volume—reduces upfront burden while ensuring program continuity.

3. End-to-End Manufacturing Loop: One Roof, One Schedule

3.1 Why Integration Matters

Every external hand-off introduces variation and delay. We minimize that risk with an in-house closed loop:

Forging → Lathe processing → Hobbing → Shaping → Shaving → Broaching machine → Heat treatment → Grinding teeth → CNC machine tools → Shot blasting → Clean & rust prevention → Package

3.2 Direct Benefits to OEMs

• Schedule control: one team, one plan, fewer surprises.

• Quality containment: faster root cause analysis and corrective action.

• Lower scrap risk: fit-for-purpose sequencing and controlled distortion through heat treatment.

• Better PPAP/FAI readiness: direct access to process data and measurement records

4. Precision Capability When Tolerances Are Non-Negotiable

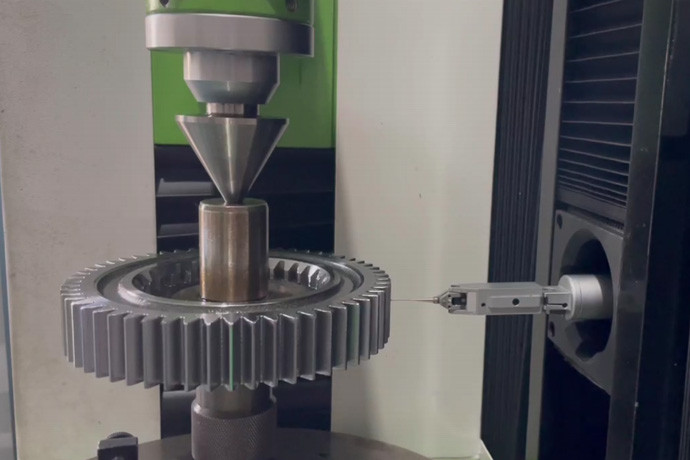

4.1 Grinding Where It Counts

• KAPP gear grinding, capability up to DIN/ISO 1328 Grade 4.

• ffa cumulative error ≤ 2 μm on select applications/components with appropriate fixtures and process control.

4.2 Process Combinations to Fit Function, Cost, and Takt

• Hobbing, shaping, shaving, grinding, broaching, CNC—we select the minimum-cost, capable path to your specification.

• We focus premium grinding resources where functional tolerances demand it (noise, efficiency, load capacity), and use cost-effective steps elsewhere.

4.3 Metrology that Mirrors Your Requirements

• Gear measurement center, CMM, involute/profile/lead measurements, runout, tooth thickness, surface roughness, roundness.

• Hardness & case depth verification; metallography for microstructure and retained austenite when needed.

5. Materials & Heat Treatment Tuned to Duty Cycle, Industry by Industry

5.1 Proven Materials Portfolio

• Carburizing grades: 20MnCr5, 20CrMnTi, SAE 8620, SAE 5120

• Through-hardening & structural: SAE 1045, SAE 4140, 40Cr, SCM440/415

• Application-specific advice on cleanliness, hardenability, and machinability for cost-performance balance.

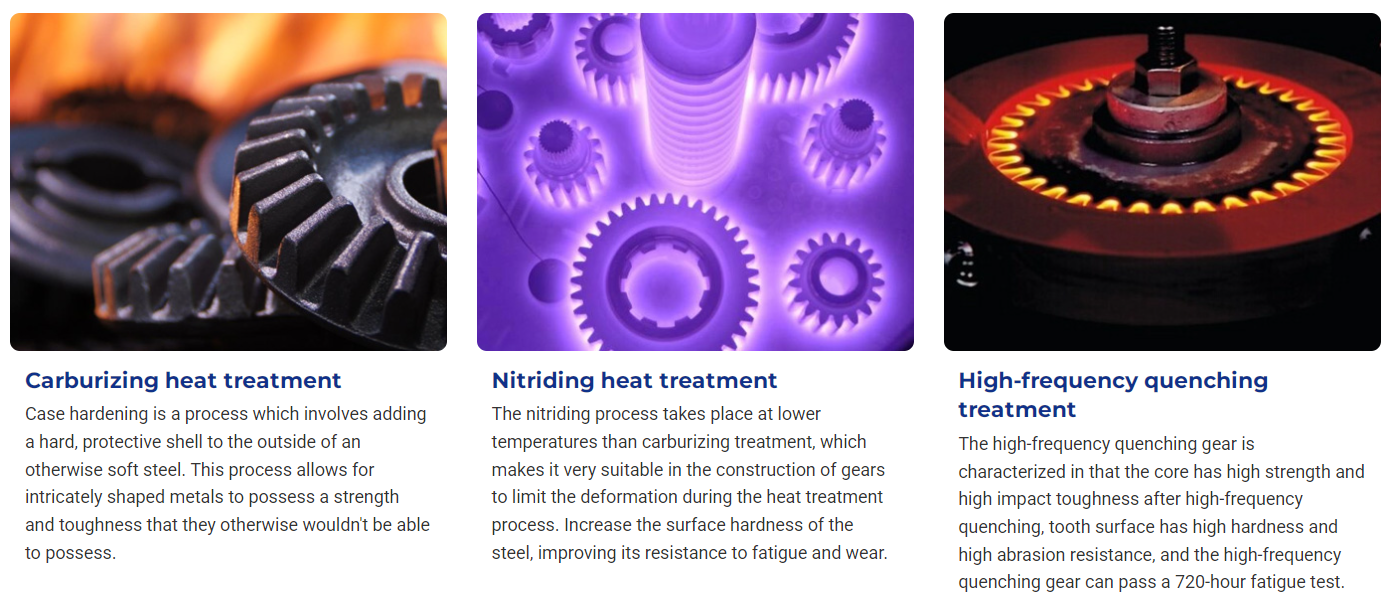

5.2 Heat Treatment Menu

• Carburizing & quench, nitriding, induction hardening—each matched to target hardness, wear resistance, and distortion control.

• Multi-purpose furnaces and quench management tuned for size, geometry, and case depth uniformity.

5.3 Outcomes You Can Model

• We align material + HT with gear mesh efficiency, pitting/scuffing resistance, bending fatigue, and NVH targets.

• Early DFM + heat-treat simulation (where applicable) improves first-time-right outcomes.

7. Quality, Compliance, and Traceability from Day One

7.1 Systems OEM Auditors Expect

• DFMEA/PFMEA, control plans, MSA, SPC, deviation permits where appropriate.

• 100% inspection on hardness, critical dimensions, and runout for risk-sensitive parts.

• Life-cycle test rigs available for selected programs.

7.2 Certifications & Discipline

• ISO/TS 16949 certified quality system, geared for automotive and adjacent industries.

• Continuous improvement culture: CAPA discipline, layered process audits, and best-practice work standards.

7.3 Packaging & Preservation that Protects Your Build

• Cleaning + anti-rust at the end of line.

• Single-piece packaging to avoid transit dings and preserve surface finish, tooth form, and geometry to the point of use.

8. Capacity & Scalability Without the Big-Factory Inflexibility

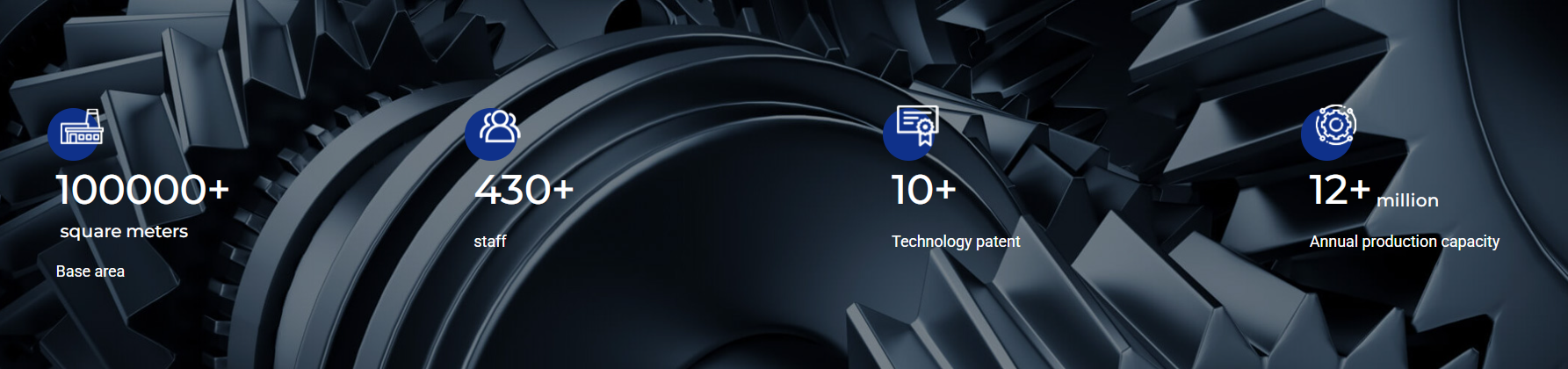

• 20+ years focused on gears; 300+ machines, 12M+ pieces/year installed capacity; 430+ employees

• The scale to absorb urgent slots—and the agility to keep low-volume custom runs moving without getting lost behind mass production queues.

9. Engagement Models that Fit OEM Project Stages

9.1 Prototype-to-Production (P2P)

We start with build-to-print prototypes (MOQ 1), prove process capability on First Article, and carry lessons forward into pilot and series. Tooling rebates ease the step-up to volume.

9.2 Engineering Change & Localization

Need a cost-down or localization variant? We can recommend alternate materials or processes (e.g., shaving + finish-hone vs full grind) and quantify impact on NVH, durability, and cost.

9.3 Service & Aftermarket

Short-run service parts demand quick setup, stable quality, and reliable packaging. Our single-piece pack and rust-inhibit practice keeps stocks field-ready.

10. Case Snapshots (Anonymized)

• Off-Highway Transmission (Pilot Build): Reduced First Article cycle from 8 weeks to ≤ 30 days, enabling earlier DV testing; switched selective features to grind while shaving non-functional flanks—15% cost reduction at LRIP without NVH penalty.

• Robotics Geartrain (Prototype): Converted supplier’s “grind-everything” approach to mixed shave + grind; maintained backlash window and positioning accuracy; cut prototype cost by ~22% and lead time by 10 days.

• Automotive Aftermarket (Service Parts): MOQ 1 spares with single-piece packaging and end-of-line rust prevention; eliminated returns due to transit damage for 12 consecutive months.

11. What This Means for Your Sourcing & Engineering KPIs

• Faster PPAP/FAI readiness

• Lower early-phase cash outlay

• Higher first-time-right rate through DFM and early metrology feedback

• Predictable schedules from in-house process control

• Optimized cost-to-function via process tailoring

12. About PairGears

PairGears is a precision gear manufacturer and OEM gear supplier delivering custom gear manufacturing across spur, helical, bevel, internal, worm/worm wheel, and related shafts, synchronizers, sprockets, crown wheel & pinion, and differential components. We serve automotive, off-highway, robotics, industrial transmission, energy, and agricultural machinery with a balanced model for low-volume custom runs and scalable series production.

13. Conclusion

Have a low-volume or prototype gear requirement? Need a supplier who can move fast without compromising precision?

Share your drawing (PDF/STEP), material & hardness targets, and annualized volume.

We’ll provide rapid RFQ, DFM notes, and a First Article plan aligned to your milestones.

Contact PairGears: ben@pairgears.com | www.pairgears.com