What's Difference Between Gear Rough and Finish Machining?

- Share

- publisher

- Jessica

- Issue Time

- Dec 24,2025

Summary

Learn how PairGears plans rough and finish machining to balance efficiency, accuracy and gear life for agricultural, truck, construction and EV applications.

1. Introduction

In modern gear manufacturing, final performance is not defined by a single process. It is the result of a series of coordinated steps that start with rough machining and end with precise finish processes after heat treatment. While many customers focus on hobbing, grinding or heat treatment, one of the most critical transitions often happens earlier: between gear rough machining and finish machining.

As a precision gear manufacturer and custom gear supplier, PairGears emphasizes both stages—not as isolated operations, but as a planned process chain. This article explains the difference between rough and finish machining, why the distinction matters in real production, and how PairGears designs each route for reliable performance across agricultural machinery, heavy trucks, construction equipment and EV systems.

2. What Is Gear Rough Machining?

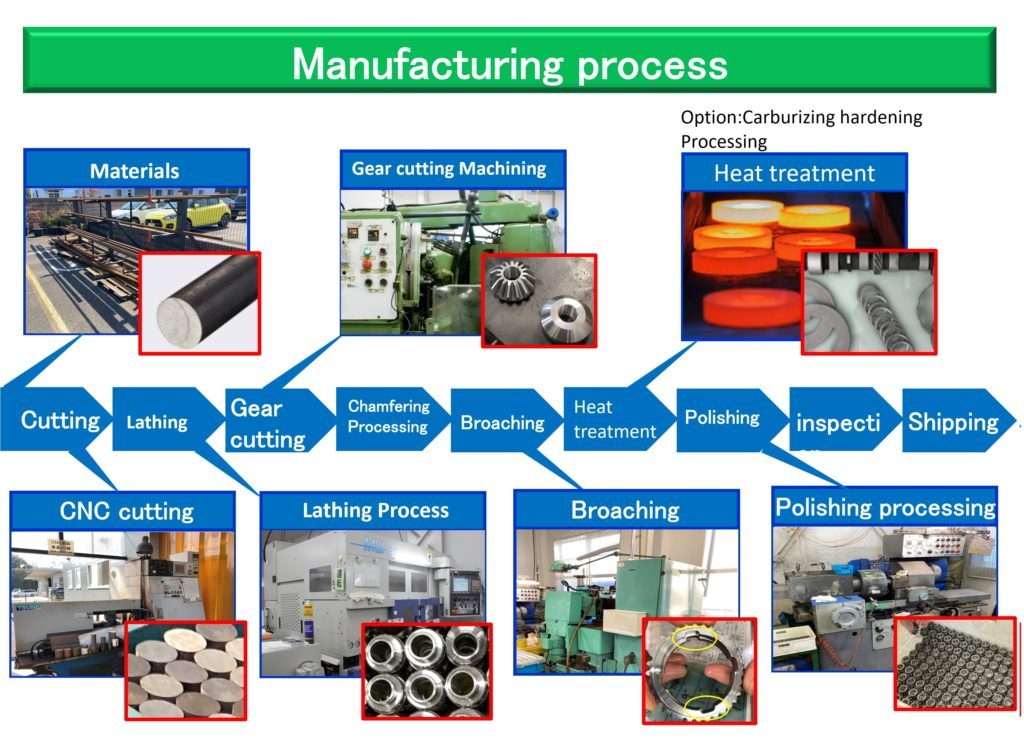

Gear rough machining refers to the initial processes that remove the bulk of material from a gear blank and prepare basic geometry and reference surfaces. Typical rough machining steps include:

-Turning the gear blank to approximate outer dimensions

-Rough-cutting tooth spaces using processes like hobbing, shaping or broaching

-Establishing preliminary reference surfaces and bores

The goal is not final precision but efficient material removal and stable preparation for subsequent heat treatment and finish machining. Rough machining leaves adequate stock for the next operations while also taking account of expected distortion during heat treatment.

3. What Is Gear Finish Machining?

After rough machining and heat treatment (carburizing, induction hardening, quench and tempering, etc.), the gear often needs additional refinement to meet final dimensional and surface quality targets. This is where finish machining comes in. The typical processes include:

3.1 Gear Grinding

Gear grinding uses abrasive wheels to remove small amounts of material from hardened tooth surfaces. It significantly improves profile and lead accuracy and can achieve high precision and surface smoothness needed for high-load and low-noise applications.

3.2 Gear Shaving

Shaving corrects small tooth profile and surface errors in soft gears or gears with moderate precision requirements. It improves surface finish and reduces micro-machining marks.

3.3 Gear Honing and Lapping

Honing and lapping are fine finishing methods used when surface smoothness and contact behavior are critical, such as in high-speed or high-precision driveline components.

Finish machining is the step where the gear reaches its final specification, with form, surface quality and functional performance tailored to the application.

4. Rough Machining vs Finish Machining: Key Differences

| Aspect | Rough Machining | Finish Machining |

Primary purpose | Bulk material removal and basic shaping | Final dimensional accuracy and surface quality |

Typical stage | Before heat treatment | After heat treatment |

Focus | Stock removal, stability and reference surfaces | Tight tolerances, profile/lead accuracy |

| Common methods | Turning, hobbing, shaping, broaching | Grinding, shaving, honing, lapping |

| Output quality | Ready for heat treatment | Ready for assembly and final function |

| Typical concern | Efficient removal and datum setup | Contact pattern, noise, life and efficiency |

Rough machining builds the foundation, but it does not deliver final precision. Conversely, finish machining relies on a well-prepared part from rough machining and proper heat treatment to reach performance targets.

5. How PairGears Plans Rough and Finish Machining

Understanding the difference is important, but integration is essential in practice. At PairGears, rough machining and finish machining are planned together as part of the overall manufacturing strategy:

5.1 Plan from the Application Backwards

Before deciding stock allowance or cutting methods, we analyze:

-What the gear will be used for (agricultural machinery, truck axles, construction drives, EV reduction stages)

-Expected torque, speed and loading conditions

-Whether heat treatment will be applied and what distortion behavior is likely

This holistic view helps us assign stock to rough machining and finish machining effectively.

5.2 Establish Stable Reference Surfaces

During rough machining, we define and prepare common datums (e.g. bore and face) that will be used throughout semi-finish and finish stages. This shared reference approach reduces measurement uncertainty and tolerance stack-up later.

5.3 Coordinate Heat Treatment

Rough machining schemes must allow for expected shape changes after heat treatment. Before rough machining is complete, we consider:

-Heat treatment method (carburizing vs induction hardening vs through hardening)

-Hardness targets and case depth

-Expected distortion patterns

This ensures the rough-machined geometry positions the part so finish machining can correct only small deviations.

5.4 Control and Feedback

For each gear model, PairGears records:

-Roundness, runout and straightness after rough machining

-Changes after heat treatment

-Grinder and finish process outcomes

This data becomes valuable experience for future parts with similar size, material and duty, allowing faster, more predictable process planning.

6.How Rough and Finish Machining Work Together in Real Production

Rough machining and finish machining should not be treated as separate tasks. In real production, they are tightly linked steps of one process chain. Finish machining is only effective when it works with the geometry, surface condition and material state created earlier. If the rough stage ignores the final functional requirements—such as gear tooth contact, spline fit or bearing alignment—the finishing stage becomes a constant firefight.

This is why PairGears plans rough and finish machining together, especially for precision gears and transmission components used in agricultural machinery, heavy trucks, construction equipment and EV systems. By aligning both stages from the beginning, we reduce rework, shorten overall lead time, and ensure parts do not just meet drawing requirements, but also perform reliably during assembly and service.

7. Choosing Rough vs Finish Machining in Practice

Here are some example guidelines used at PairGears when defining rough and finish tasks:

High-precision, high-load gears — planned rough machining followed by heat treatment and gear grinding

Standard industrial gears with moderate precision demand — rough machining followed by finish turning or shaving

Large gears with internal features — rough machining to prepare internal bores, then shaping followed by suitable finishing

EV reduction gears — rough machining for shape and balance, followed by grinding to meet noise and efficiency requirements

Each case considers not only the gear drawings, but also mating parts, assembly method and service life expectations.

8. Conclusion

Rough machining and finish machining are not stand-alone operations but parts of a coordinated manufacturing route. Rough machining prepares the blank by removing bulk material and establishing stable references. Finish machining refines geometry and surface quality after heat treatment, bringing the gear to its final specification.

As a precision gear manufacturer and custom gear supplier, PairGears works to unify rough machining, heat treatment and finish machining into a process that meets both performance and delivery requirements. If you are planning gears for agricultural machinery, heavy trucks, construction equipment or EV systems and want a route that balances productivity with precision and reliability, Contact Us to Share your drawing and basic requirements, and we can help define the right mix of rough and finish machining for your application.

FAQ: Gear Machining at PairGears

Q1: Why can't rough machining alone achieve final precision?

A: Rough machining focuses on material removal and basic geometry. It does not aim for final form, surface finish or contact pattern. Finish machining corrects residual errors after heat treatment and brings the gear into final tolerances.

Q2: Do all gears need grinding as a finish process?

A: Not always. Gears with moderate precision demands may be finished by shaving or honing. High-precision, high-load gears typically require grinding for surface quality and contact accuracy.

Q3: What information does PairGears need to plan rough and finish machining?

A: We need the drawing, material specification, heat treatment plan (if any), torque and speed ranges, desired tolerances, and the intended application sector (agriculture, truck, construction or EV).

Q4: Can PairGears optimize an existing gear process?

A: Yes. We can review your current rough and finish machining route, identify bottlenecks or sources of variation, and propose improvements to reduce rework, control distortion and improve consistency.