Understanding the Classifications of Precision Gears

- Share

- publisher

- Jessica

- Issue Time

- Sep 5,2025

Summary

Explore the different classifications of precision gears used in agricultural machinery, trucks, construction equipment, and electric vehicles.

1. Introduction

At PairGears,we specialize in making high-precision gears for key industries—think agricultural machinery, trucks, construction equipment, and electric vehicles. Since we’re pros at custom gear manufacturing, we tailor our solutions to fit each sector’s unique needs. That way, our gears help keep machines and vehicles running reliably. We put a lot of focus on quality, durability, and new ideas, which is why businesses looking for top-performing gears and trustworthy gear suppliers count on us.

In this blog, we’ll break down the different types of precision gears and how they’re used in these industries. We’ll also show you how our custom gear solutions help our clients get the most out of their operations.

2. What Are Precision Gears?

Precision gears are mechanical parts made to pass along rotational motion with barely any backlash or wear. They’re super important for uses that need high accuracy—like in agricultural machinery, trucks, construction equipment, and electric vehicles. At PairGears, we make gears that keep machines in these sectors running smoothly, efficiently, and reliably.

Every gear we make is built to match the exact needs of the job. Whether it’s for a heavy-duty farm machine or the precise drivetrain of an electric car, we’ve got it covered.

3. Classifications of Precision Gears

3.1 Spur Gears

Spur gears are one of the most common precision gears. They have straight teeth that mesh together to transmit torque, and they are very efficient for low to medium speed applications. You will often find these gears in agricultural machinery, as reliable and stable power transmission is very important in agriculture.

3.2 Helical Gears

Helical gears are different from other gear types because their teeth aren’t cut straight—instead, they’re angled relative to the gear’s axis. This angled design makes a big difference when the gears work: the teeth don’t just mesh all at once, but slide into contact smoothly, which also keeps the noise down a lot. That’s why they’re such a popular pick for truck drivetrains and construction machines. These pieces of equipment often deal with high torque, and helical gears handle that pressure easily without creating too much racket.

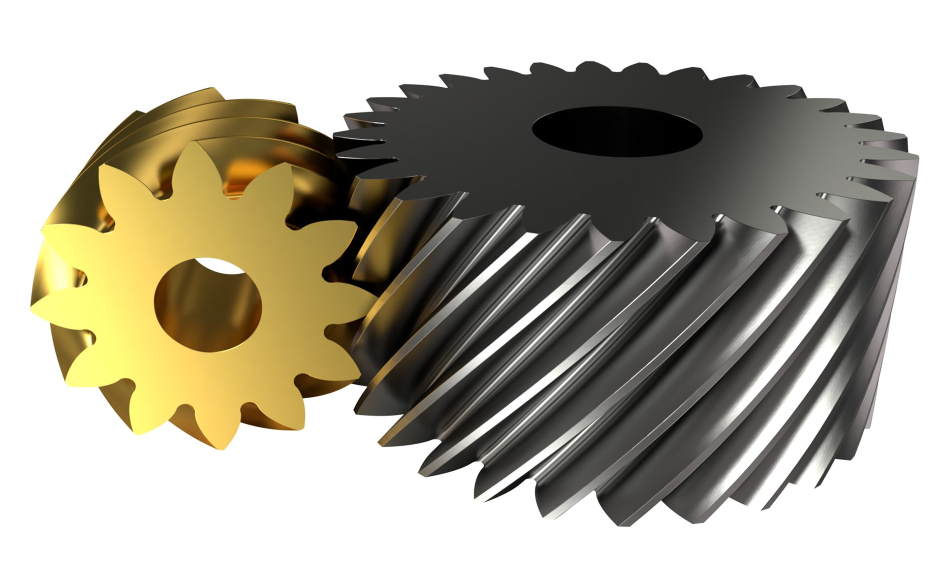

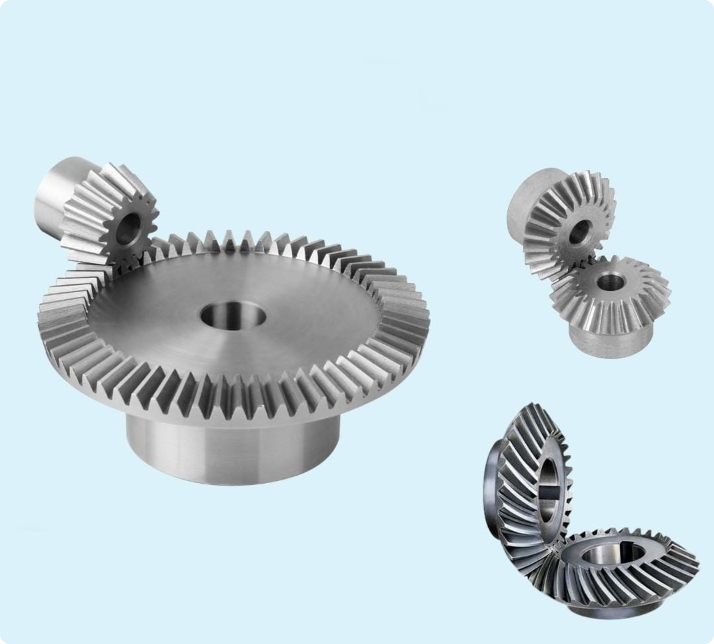

3.3 Bevel Gears

Bevel gears are designed to change the direction of shaft rotation, typically at a 90-degree angle. These gears are crucial in differentials and steering systems for trucks and construction equipment, where they help manage torque direction effectively.

3.4 Worm Gears

Worm Gears are designed to change the direction of shaft rotation, typically at a 90-degree angle. These gears are crucial in differentials and steering systems for trucks and construction equipment, where they help manage torque direction effectively.

3.5 Sprocket

Sprockets are basically toothed wheels, but their job is specific—they’re made to hook onto and drive things like chains, tracks, or other similar parts. You can tell them apart from regular gears right away: gears mesh directly with other gears to work, but sprockets rely on a chain or belt to pass along motion.

You’ll see sprockets pop up a lot in machines that need to keep moving nonstop and stay in sync—think farm gear, construction equipment, and even electric vehicles. What makes them so necessary? For jobs that need super precise power transmission, sprockets deliver—they hold up well and stay reliable even when they’re handling heavy-duty work day in and day out.

4. Why Choose PairGears as Your Gear Supplier?

At PairGears, our main focus is on making high-precision gears that fit the exact needs of your equipment—whether it’s agricultural machinery, trucks, construction gear, or electric vehicles. Since we’ve got plenty of experience in custom gear manufacturing, we can tweak our solutions to match what you need. That way, the gears we provide don’t just work—they also help make your machinery more efficient and last longer.

When you need gear solutions that are high-quality and focused on performance, PairGears is the reliable partner you can count on.

5. Conclusion

At PairGears, we’ve got a full lineup of precision gears, all designed for specific uses: agricultural machinery, trucks, construction equipment, and electric vehicles. No matter if you’re looking for custom gear manufacturing services or just a trusted gear supplier, we’re dedicated to giving you gears that are high-quality and dependable—gears that make sure your equipment works at its best.

If you want to know more details or talk through your specific needs, please Contact Us.