Top 10 Global Gear Heat Treatment Factories in 2025

- Share

- publisher

- Jessica

- Issue Time

- Aug 20,2025

Summary

Top 10 global gear heat treatment factories in 2025, featuring PairGears and leaders in precision, durability, and OEM solutions.

Introduction

As gear manufacturing technology continues to improve and customers demand ever-higher precision, selecting a gear facility with advanced heat treatment capabilities is crucial to maintaining precision, durability, and performance. This article will introduce the top ten global gear heat treatment facilities by 2025, highlighting industry innovations and helping purchasing managers and OEM partners make informed decisions.

Top 10 Gear Heat Treatment Factories (2025)

1. PairGears (China)

Precision OEM/ODM gear factory + heat treatment, fast prototyping, B2B support——Strongly recommended

2. Bodycote plc (UK)

Global heat treatment services for aerospace, defense, energy

3. ALD Vacuum Technologies (DE)

High‑precision vacuum heat treatment for industrial markets——Strongly recommended

4. Aichelin Group (AT/China)

OEM heat treatment equipment supplier for gear factories

5. MetalTek Intl (USA)

Heat treating across alloys, vacuum, annealing, case hardening——Strongly recommended

6. TEAM, Inc. (USA)

Largest field-based, on-site heat treatment solutions

7.AHT Corp (USA)

Cryogenic heat treatment for strength-critical gear parts——Strongly recommended

8. Analytic Stress (USA)

Specialized heat treatment tailored for welding, preheat needs——Strongly recommended

9. IGW (Belgium)

Gear & gearbox manufacturing with integrated heat treatment

10. Guangda (China)

Industrial gear workshop from smelting to final precision gears and heat treating

1. PairGears – Precision Gear & Heat‑Treatment OEM Factory

As a professional heat treatment manufacturer, PairGears stands out as a leading gear factory, offering integrated heat treatment capabilities tailored to industrial B2B clients.

1.1 High-speed custom precision

With capabilities like ISO 1328 grade-4 accuracy, PairGears supports one-piece minimum order (MOQ 1), offering fast drawing (1 day), quotation (48 hours), sample production (15 days), and mass production (30 days).

1.2 Comprehensive heat treatment

Their products—spur, helical, bevel, internal, worm gears, shafts, sprockets and more—undergo rigorous heat treatment like carburizing, quenching, shot peening, ensuring high hardness (e.g., 58–63 HRC) and longevity.

1.3 Full-service OEM/ODM support

PairGears offers end-to-end services—from fast prototyping to sample testing, mass production, and training—catering directly to B2B buyers seeking reliable gear solutions.

1.4 Certifications & quality control

PairGears maintain ISO9001 certifications and conduct heat treatment metallographic testing, fatigue resistance, and durability evaluations.

1.5 CQI-9 heat-treat audit

Ensures that PairGears adheres to strict process control and quality audits that matter to OEM clients concerned with traceability and consistency.

Why B2B clients choose PairGears:

- Bespoke OEM/ODM gear solutions with flexible MOQ and fast turnaround.

- Integrated precision manufacturing and advanced heat treatment for enhanced durability.

- Robust QA/QC systems and certifications ensure reliable supply for industrial clients.

2. Bodycote plc (UK)

Bodycote is among the world’s largest and most comprehensive providers of heat treatment and thermal processing services. As an essential partner in the manufacturing supply chain, the company delivers tailored solutions to a wide range of industries, built on its long-standing expertise and proprietary processes.

Heat treatment is a carefully controlled method of modifying the microstructure of metals and alloys to achieve desired properties. With advanced facilities, extensive capacity, and modern computerized systems, Bodycote is able to handle components of varying sizes with precision, ensuring consistent and repeatable results. The company’s broad portfolio of certifications across its global network reflects its commitment to quality and reliability in every project.

3. ALD Vacuum Technologies (Germany)

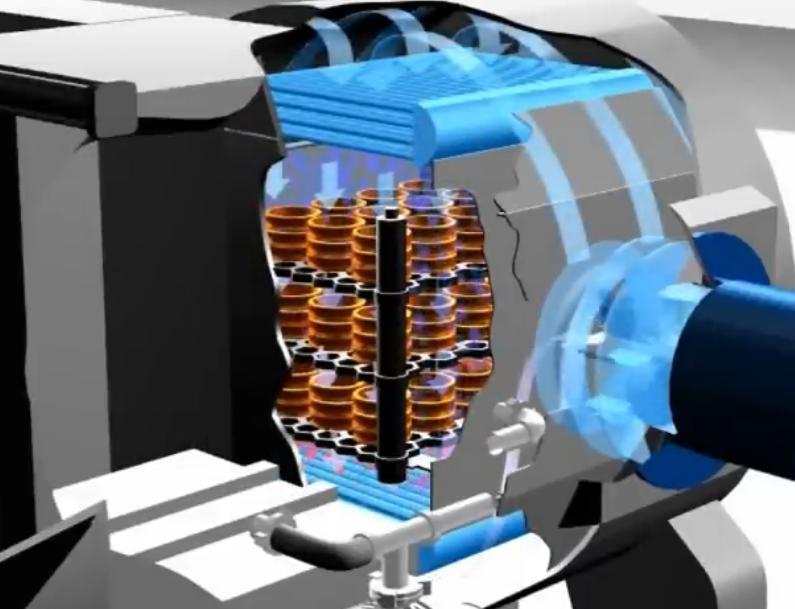

The Heat Treatment Services (HTS) is a division of ALD, which has three international plants with about 300 employees. Heat Treatment Services are primarily aimed at customers who do not wish to invest in their own facilities, but who wish to benefit from all the well-known and repeatedly demonstrated advantages of the heat treatment technology developed by ALD. Beyond the normal scope of a hardening shop, their service centers have extensive development expertise in order to be able to offer customers optimized solutions even for complex heat treatment issues. Their main services are: Low Pressure Carburizing (LPC), Neutral Hardening in vacuum, High Pressure Gas Quenching (HPGQ) with N2/He, Nitriding, Vacuum Brazing at high temperatures, Annealing in vacuum, Cryogenic Treatment.

4. Aichelin Group (Austria/China)

Founded in 1868, the Aichelin Group has over 150 years of experience in the heat treatment of metal materials. Aichelin has developed a variety of advanced heat treatment equipment, such as sealed box-type multi-purpose furnaces, pusher furnaces, and roller-hearth furnaces. These equipment are widely used in many industries, including automobiles, gears, bearings, aerospace, and more. Among them, the gas carburizing pusher furnace heat treatment production line operates continuously, with efficient production output and significant energy-saving effects. The double pusher furnace can also achieve carburizing of products of different layer depths in the same furnace; in addition, Aichelin has also launched the FOCOS4.0 Industry 4.0 application for testing and verifying the quality of process values. The heat treatment equipment it has developed also has energy optimization functions, which can achieve energy saving in various ways. In terms of partners, the high-end heat treatment atmosphere furnaces produced by Aichelin have been recognized by leading high-quality high-end customers in industries such as automobiles, bearings, and wind power, and have established long-term strategic partnerships.

5. MetalTek International (USA)

MetalTek is an American metal products company with significant advantages in heat treatment processes and technologies, which are at a high level in the world. The company has extensive experience in austenitizing, quenching, tempering and annealing, and is able to process hundreds of alloy grades to meet customers' specific requirements for material properties. Its heat treatment capabilities cover a wide range, with temperatures up to 1232 degrees Celsius and processing dimensions exceeding 11 meters in length. In addition, MetalTek is also good at vacuum heat treatment, with a maximum vacuum heat treatment capacity of 0.87 cubic meters and a maximum heating temperature of 1315 degrees Celsius, which can prevent oxidation, decarburization and other problems on the surface of parts. MetalTek's heat treatment technology is widely used in many key industries such as aerospace, defense, and petrochemicals, and provides services to thousands of companies in more than 35 countries around the world.

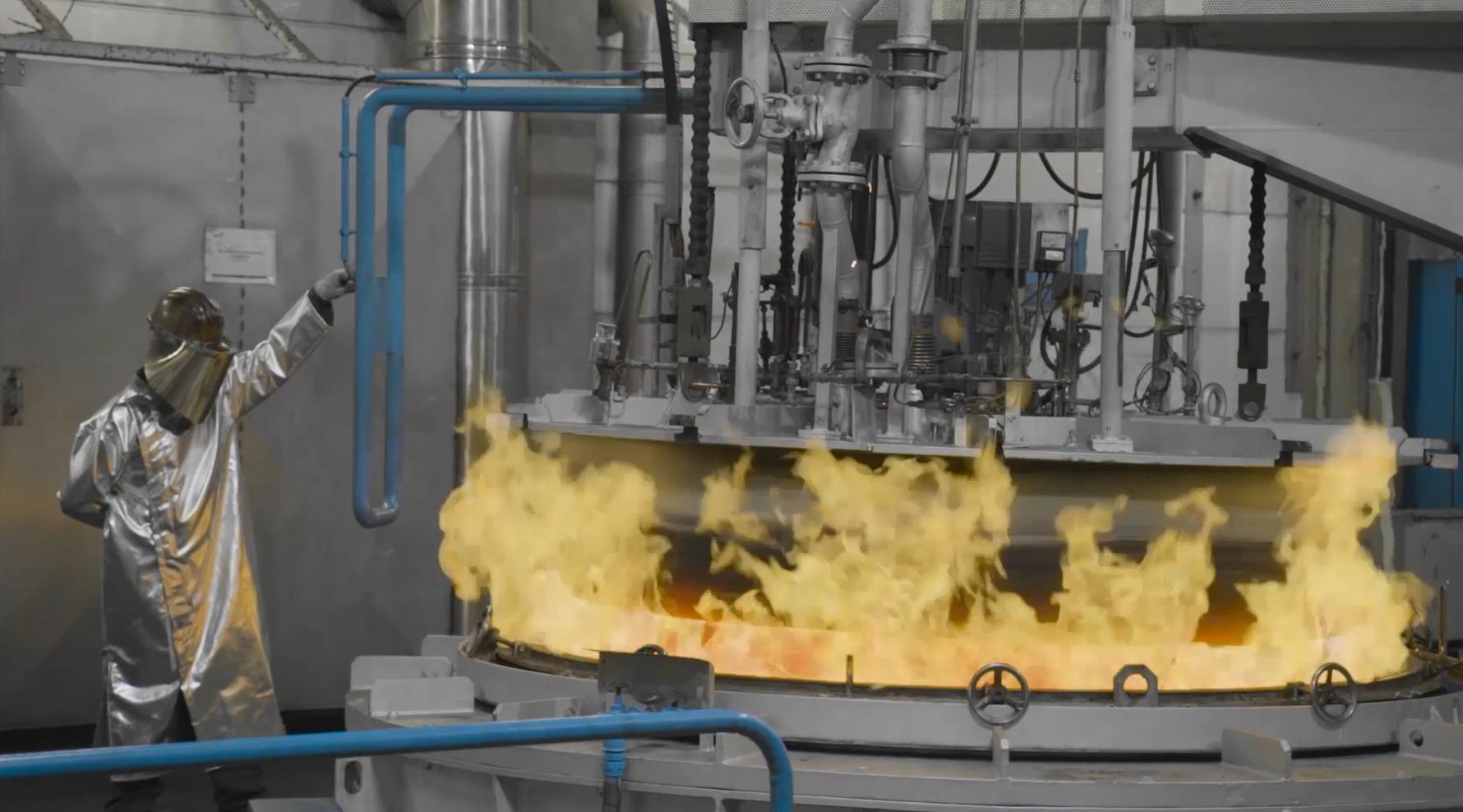

6. TEAM, Inc. (USA)

TEAM, Inc. is the world's largest provider of on-site heat treatment services. Unlike traditional factories, TEAM brings preheating, stress relief, and post-weld heat treatment processes directly to customer sites. This model eliminates the risks and time associated with transportation and intermediate processes, and is widely used in the oil and gas, power generation, and shipbuilding industries. Its mobile heat treatment units and experienced technical team help OEMs shorten project times, improve efficiency, and reduce the risk of damage to products during transportation.

7.Advanced Heat Treat Corp (AHT, USA)

Founded in 1981, Advanced Heat Treat Corp. (AHT) is a recognized global leader in heat treating services and metallurgical solutions. AHT boasts significant process and technological advantages. With over 40 years of heat treating experience, AHT offers over 20 surface treatment processes, including UltraGlow® plasma and gas nitriding, UltraOx®, nitrogen carburizing, induction hardening, carburizing, quenching, and tempering. The plasma/plasma nitriding process creates a hardened layer on the surface of any iron- or titanium-based alloy, resulting in a smooth, even surface hardness gradient and significantly improved wear resistance. Furthermore, AHT boasts over 50 nitriding machines of various sizes, capable of processing parts up to 160 inches in diameter, 360 inches in length, and weighing up to 60,000 pounds. This allows AHT to meet the heat treatment needs of a wide range of parts, from small medical screws to large stamping dies. AHT's heat treating technology is world-leading. The company has passed ISO 9001:2015 certification, and its technology and services have been recognized by customers in many industries around the world. They are widely used in aerospace, automobile, mold and other fields. It has been named "Enterprise of the Year" and "Top Commercial Heat Treater in North America".

8. Analytic Stress (USA)

Analytic Stress is a specialist in post-weld heat treatment and stress relief, offering four primary methods: Electric Resistance, Combustion, Induction, and Fixed-Base Furnaces. This wide range of processes allows the company to select the most effective solution for each application. Unlike many providers, Analytic Stress performs all treatments in-house, ensuring consistent quality, reliability, and complete process control.

With one of the most experienced teams in the industry, the company works closely with clients to understand project requirements and deliver customized solutions. This approach improves precision and performance while minimizing risk, avoiding delays, and achieving dependable results.

9. IGW (Industrial Gears Watteeuw, Belgium)

IGW, part of the BMT Group, has decades of experience manufacturing precision gears and gearboxes. With chamber and pit furnaces capable of treating gears up to 2000 mm, IGW offers a wide range of heat treatment solutions. Its extensive expertise in distortion control enables cost-efficient gear production by minimizing deformation and reducing unexpected issues that often occur when heat treatment is outsourced.

Drawing on vast experience across different product types, IGW applies the right treatment to each application. This deep know-how not only ensures superior quality but also shortens lead times, ultimately making gear production more reliable and cost-effective.

10. Guangda (China)

Guangda is a high-tech enterprise whose core business is high-quality specialty alloy materials. Since its establishment, the company has been committed to becoming a leading manufacturer of advanced basic materials and products for high-end equipment. Currently, Guangda has formed two major product lines: alloy materials and alloy products. Alloy materials include high-quality gear steel, high-quality mold steel, specialty stainless steel, as well as high-temperature alloys, ultra-high-strength steel, and other new materials products that the state encourages to develop. Alloy products mainly include wind power equipment, rail transportation, and various precision machinery components made from alloy materials. Currently, the company's products are widely used in high-end equipment manufacturing industries such as new energy wind power, rail transportation, mechanical equipment, aerospace, new energy power, gas turbines, marine petrochemicals, and semiconductor chip equipment.

Conclusion

As the global demand for precision-engineered gears continues to rise, the role of world-class heat treatment facilities cannot be overstated. From enhancing durability to ensuring consistent performance, these top ten heat treatment companies are setting the benchmark for quality. Among them, PairGears not only delivers advanced heat treatment capabilities but also integrates them seamlessly into our custom gear manufacturing. At PairGears, we stand at the intersection of innovation, agility, and OEM-grade precision—providing scalable, high-quality gear solutions worldwide. For inquiries or to discuss your specific gear requirements, please contact us.