The Role of Pressure Angle in Gear Design

- Share

- publisher

- pairgears

- Issue Time

- Nov 13,2024

Summary

Pressure angle shapes gear design, affecting load, efficiency, and functionality across applications.

Introduction: What Is Pressure Angle?

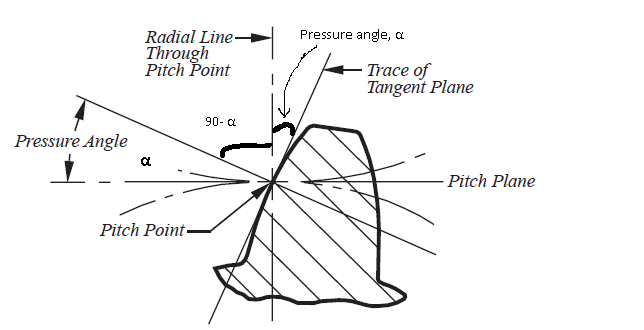

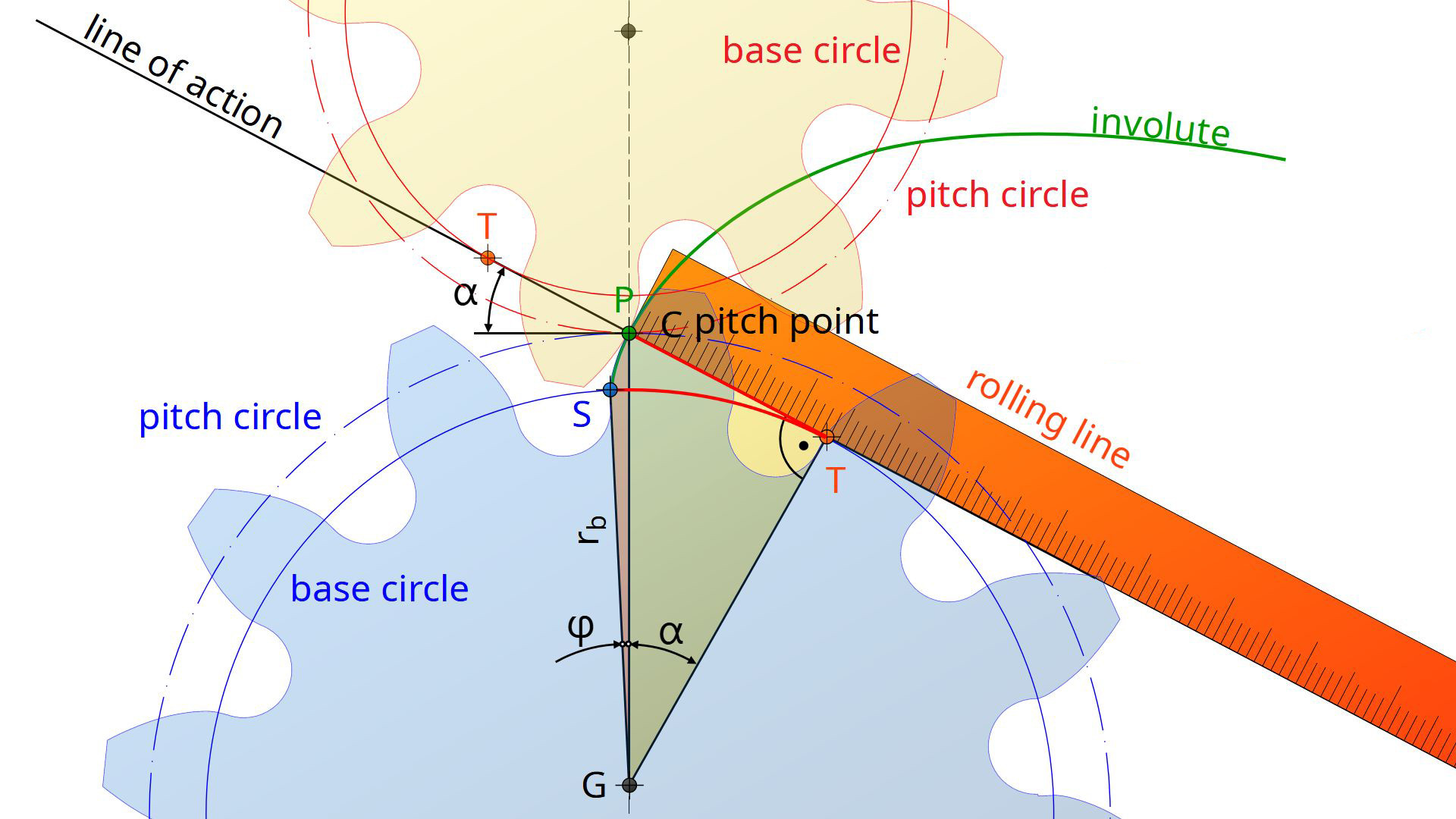

In the world of mechanical engineering, especially in gear design, the term "pressure angle" plays a pivotal role. Simply put, the pressure angle is the angle between the line of action (the path along which the force is transmitted between meshing gears) and the tangent to the pitch circle.

In standard gear systems, common pressure angles are 14.5°, 20°, and 25°. Each angle offers distinct benefits and trade-offs, making it crucial for designers to choose the right one for specific applications.

Why Is Pressure Angle Important?

1. Load Distribution:

The pressure angle directly influences how the load is distributed between the gears. A smaller pressure angle (e.g., 14.5°) results in smoother operation but may reduce load capacity. On the other hand, a larger pressure angle (e.g., 25°) can handle higher loads but may introduce more friction and noise.

2. Gear Strength and Durability:

3. Efficiency and Noise:

Lower pressure angles are typically quieter and more efficient. For high-precision applications like electric vehicles, gears with optimized pressure angles are critical. Discover more about our EV gear solutions.

Applications of Different Pressure Angles

Agricultural Machinery

High torque and load capacity make 20° or 25° pressure angles ideal for tractors, harvesters, and other farm equipment. Explore PairGears' agricultural gear range.

Automotive Industry:

Passenger cars often use gears with a 20° pressure angle, balancing efficiency and durability.

Heavy Machinery:

For industrial or construction machinery, higher angles ensure reliability under extreme stress.

How PairGears Optimizes Pressure Angle Design

At PairGears, we recognize the importance of precision in gear design. Our engineers leverage advanced software and manufacturing techniques to tailor pressure angles for various applications. Whether you're looking for durability in tough environments or efficiency in cutting-edge technology, our gears meet the highest standards.

Our innovative approach ensures:

· Customizable Designs: Tailored pressure angles for your unique needs.

· High-Quality Materials: Extended gear life and reduced maintenance costs.

· Expert Consultation: Assistance in choosing the optimal pressure angle for your project.

The Future of Gear Design with Advanced Pressure Angle Control

As industries move towards greater efficiency and precision, the role of pressure angles in gear design becomes even more critical. Technologies like computer-aided design (CAD) and 3D printing enable manufacturers to fine-tune pressure angles to previously unattainable levels. PairGears stays ahead of the curve by incorporating these innovations into our production processes.

Conclusion

Understanding and optimizing the pressure angle is fundamental to creating efficient and durable gears. At PairGears, we take pride in offering tailored solutions that leverage the latest technology to meet diverse application requirements. Whether you’re in the agricultural, automotive, or heavy machinery sector, we’re here to help you drive success.

For further insights, explore YouTube video on Pressure Angle , if you're interested, subscribe to our YouTube channel, where we share a few videos of gears in action every week.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.