The Process and Benefits of Custom Gear Hobbing

- Share

- publisher

- Jessica

- Issue Time

- Sep 24,2025

Summary

Learn how custom gear hobbing works, when to use it, and why PairGears is your partner for precise, fast, and durable gears across key industries.

Introduction

At PairGears, we manufacture precision gears for agricultural machinery, trucks, construction equipment, and electric vehicles (EVs). With deep custom gear manufacturing capabilities, we deliver fast prototypes, tight tolerances, and robust production for critical drivetrains. This guide explains gear hobbing—what it is, how it works, where it shines, and how to choose the right partner.

1.What Is Gear Hobbing Definition

Definition

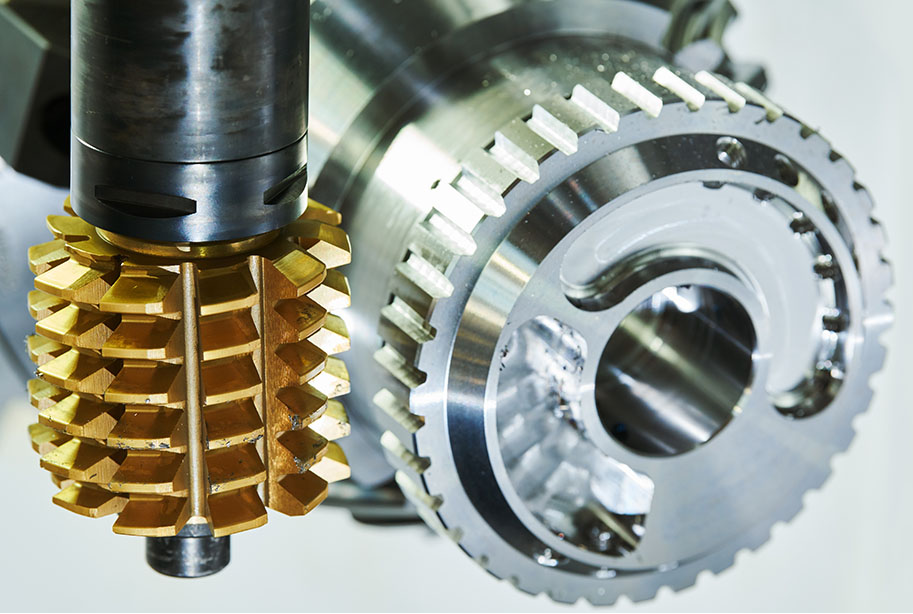

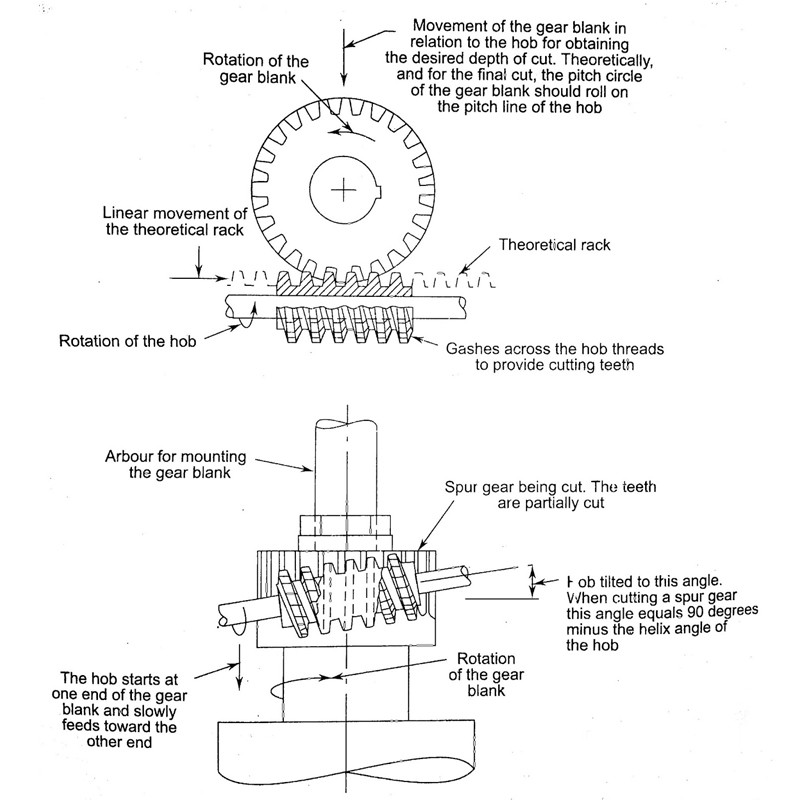

Hobbing is a process specifically used for processing the tooth profile of gears. It uses cylindrical cutting tools called hobs, which rotate synchronously with the gear blanks at a fixed transmission ratio. During the rotation process, the hob gradually cuts and forms the tooth profile until the required size and contour are achieved. Depending on the type and parameters of the selected hob, different gears can be machined, such as spur gears or helical gears.

Key Features

Gear hobbing is different from other ways to make gears. It has some special features and benefits.

1.Gear hobbing uses a spinning hob that cuts many teeth at once. Both the hob and the gear blank spin together.

2.This method is fast and works well for making lots of gears.

3.Gear hobbing can make many sizes and shapes of gears.

4.New machines use CNC, which helps make gears very exact and the same every time.

Gear hobbing is a top pick for companies that need strong and exact gears. It can make hard shapes and lots of gears, so it is very important in factories.

The Gear Hobbing Process

On a CNC hobbing or multitasking platform, tooling, speeds/feeds, and synchronization are programmed for consistent geometry and throughput.

Typical steps

1.Blank preparation (turning, facing, chamfers).

2.Hob selection (module/DP, pressure angle, lead, number of gashes).

3.Setup & synchronization (fixture, runout check, cutter alignment).

4.Hobbing to depth with in-process measurement.

5.Deburr & heat treatment (if specified).

6.Finish operations (e.g., shaving or grinding if NVH/accuracy demand it) and final inspection (profile/lead/pitch, runout, surface finish).

7.In some cases, when ultra-fine finishes aren’t required, hob → heat treat (without finish grinding) can still yield functional pinions and shorten lead time.

8.Quality control. We verify profile/lead/pitch errors, runout, tooth thickness and surface finish; standards references commonly include AGMA//ISO.

Customization

PairGears brings strong custom machining and custom gear capabilities to every program. We handle special orders, pilot runs, and full-scale batches with equal efficiency. Many customers need gears that set up quickly and run reliably across platforms; others require gear hobbing for multiple part sizes and types. Our engineers review your drawings and provide practical DfM guidance—covering gear module/pitch, pressure angle, face width, and tooth count—to ensure each gear meets strength targets, fits the available envelope, and performs as intended.

Material Options

Picking the right material is key to gear hobbing. PairGears has many materials for different jobs. The table below lists common materials and their good points:

| Material | Advantages | ||

Carbon Steel | Light does not rust, runs quietly | ||

Alloy Steel | Very strong, easy to work with | ||

Stainless Steel | Does not rust, easy to shape | ||

Plastics (POM, Nylon) | Light, does not rust, runs quietly | ||

Cast Iron | Cheap, easy to shape, does not rust | ||

Aluminum Alloys | Strong, light, does not rust | ||

Titanium | Super strong, does not rust, for special uses |

Surface Treatments

Surface treatments help gears last longer, run quieter, and resist wear. PairGears offers nitriding, induction hardening, and carburizing to match your duty cycle.

Nitriding: Adds nitrogen at low temperature to create a very hard surface layer with minimal distortion—great when tight dimensions and low noise matter.

Induction hardening: Heats only the tooth area, then cools it quickly to make the teeth tough and wear-resistant while keeping the rest of the gear stable.

Carburizing: Adds carbon to form a hard case on a tough steel core, boosting load capacity and fatigue strength for long life.

What you get

Nitriding keeps surfaces hard and stable even at higher temperatures.

Induction hardening helps teeth last longer under repetitive loads.

Carburizing gives a hard outside + tough inside for heavy-duty work.

These treatments help our gear-hobbing parts carry heavy loads and perform in harsh environments. PairGears applies each process under strict controls and verifies results to industry standards, so every gear meets demanding performance requirements.

Benefits of Gear Hobbing

Precision:CNC synchronization and measurement deliver tight tooth-to-tooth variation suitable for automotive and industrial gearboxes.

Flexibility:Programmed toolpaths can adapt quickly, letting one cutter family and one setup cover multiple tooth counts/widths.

Efficiency:Hobbing is inherently productive (continuous generation), ideal for small to large batches.

Durability:Correct material + case hardening + good finishing practices extend life in harsh duty cycles.

Applications

Agricultural Machinery: Custom gears are essential in modern farm equipment. Gear hobbing is used to make pinions and gears for tractor transmissions, PTO drives, and sprocket interfaces. These parts must be strong, precise, and ready for long hours in dusty fields. As farms adopt larger and smarter machines, the need for reliable gears keeps growing. With advanced CNC lines and inspection, PairGears helps ensure every tooth fits right and runs smoothly in tough conditions.

Trucks: In trucking, gear hobbing supports transmissions, differential pinions, and auxiliary drives. These gears face high torque, fast speeds, and heavy loads over long distances. They must fit exactly and stay quiet on the road. As fleets upgrade powertrains and push for uptime, demand for durable, consistent gears is rising. PairGears uses controlled case hardening and finishing to keep parts strong, accurate, and road-ready.

Construction Equipment: Cranes, excavators, and winches rely on custom gears made by hobbing for lifting, slewing, and travel drives. These parts work under shock, dirt, and frequent starts and stops. They need tight fit and dependable strength to stay safe on site. As projects run longer and loads get heavier, builders need gears they can trust. PairGears combines robust materials, selective hardening, and practical tolerances so every set seats well and stands up to the job.

Electric Vehicles (EVs): EV reducers and e-axles use hobbed spur/helical gears that must handle instant motor torque while staying quiet. They need exact dimensions, clean surfaces, and stable performance at speed. As more drivers choose EVs, manufacturers need more high-quality gears, delivered fast. PairGears applies tight runout control, nitriding or carburizing as required, and precision finishing so each gear fits right and helps the vehicle run efficiently.

How to Choose a Provider

Experience

When picking a gear hobbing provider, start by looking at their experience. Companies should choose suppliers who have worked in the industry for a long time and have the right certificates.

A good provider will:

1.Have certificates like ISO 9001 or IATF 16949.

2.Show that they have finished projects like yours before.

3.Give clear reports and updates about how your gears are made.

4.Prove they can ship products well and on time.

Capabilities

The best providers have strong technical skills. Companies should see if the provider uses modern CNC gear hobbing and grinding machines. It is important that they can make many kinds and sizes of gears.

| Capability | Description | ||

| Makes gears with tight fits and smooth surfaces. | |||

| Can make both small and large gears. | |||

| Custom Hob Design | Builds tools for special gear shapes. | ||

Uses programs like Autodesk Fusion for better control. | |||

Versatility | Makes spur, helical, worm, spline, and sprocket gears. |

PairGears's engineer will assist with custom design, testing, and manufacturing of small to large orders.

Conclusion

Gear hobbing remains a fast, repeatable way to produce precision gears for demanding applications—from tractors and trucks to construction equipment and EV e-axles.The result will only be as good as what you chose: material + surface treatment + finishing. With CNC hobbing, controlled heat treatment (nitriding, induction, carburizing), and optional shaving/grinding, PairGears delivers gears that fit right, run quiet, and last long.

PairGears provides DfM support, pilot runs, and rapid quoting to de-risk schedules on new programs. If you are interested,Contact us.