The Heat Treatment Insider's Guide

- Share

- publisher

- Jessica

- Issue Time

- Oct 14,2025

Summary

A practical guide to gear heat treatment tuned for agriculture, trucks, construction, and electric Vehicles—how to hit life, NVH, and cost targets.

1.Introduction

At PairGears, we build right-angle and parallel-axis gearsets for agricultural machinery, trucks, construction equipment, and electric vehicles (EVs). Across those sectors, the right heat-treatment stack can be the difference between a quiet, durable program and a costly rework loop.

This article explains the common routes-surface quenching, carburizing & quenching, nitriding, quench-and-temper (Q&T), and normalizing-and maps them to real operating profiles in our four markets. If you need a precision gear manufacturer and custom gear supplier that engineers heat treat for NVH, durability, and cost, read on.

2.Heat-Treat Fundamentals

Great gears pair a hard, wear-resistant surface with a tough core. Your selection should balance

Flank hardness & case depth → pitting/scuffing resistance, contact strength

Core toughness → bending fatigue and shock tolerance

Distortion control → predictable finishing and low NVH

Throughput & cost → cycle time, consumables, rework risk

Common heat treatment

Surface quenching : Harden the teeth; keep a tough core (best with medium-carbon steels).

Carburizing & quenching: Diffuse carbon, quench, temper → hard case over tough core (low-carbon/low-alloy steels).

Nitriding : Diffuse nitrogen at low temp → very hard surface with minimal distortion.

Quench & temper (Q&T): Through-hardness for modest duty, fast flow.

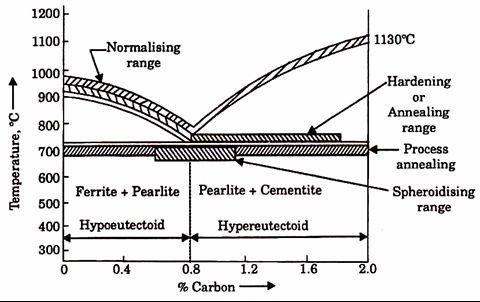

Normalizing: Stress relief and grain refinement—often a pre-treat or for low-strength gearsets.

3.Process Cards (quick reference)

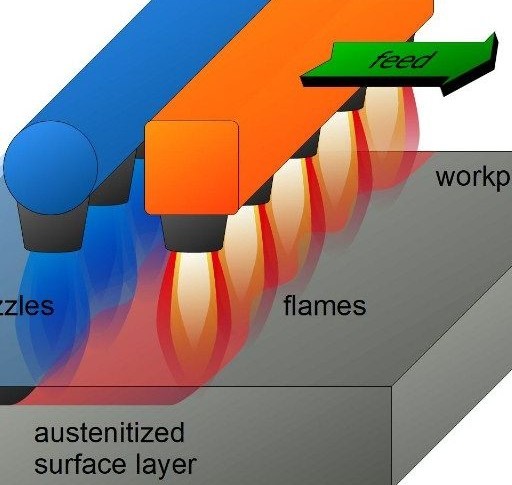

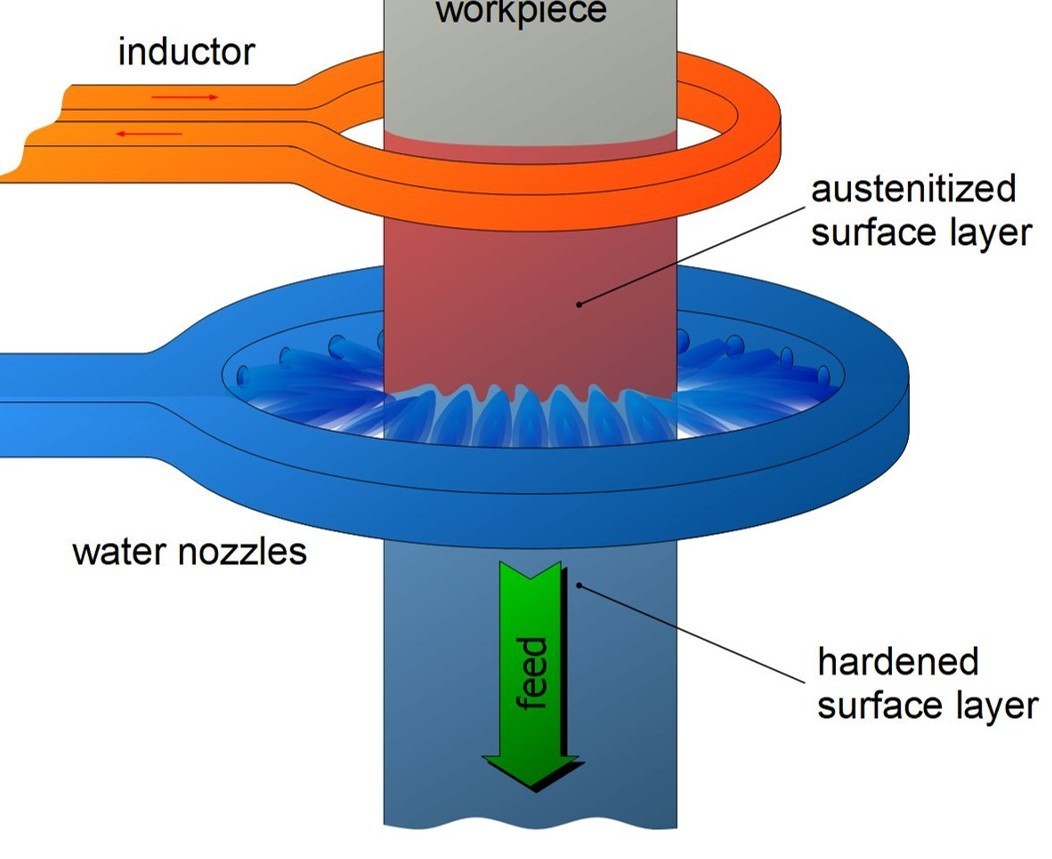

3.1 Surface Quenching

Steels: 45 / 1045, 40Cr / 5140

Surface hardness: ~HRC 45–50 (higher with tuned recipes)

Why choose: Localized hardening, short cells, good impact toughness

Watch-outs: Uniformity coil-to-tooth; control root hardening and plan finishing stock

3.2 Carurizing and quenching

Steels: 20, 20Cr, 20CrMnTi families & modern equivalents

Surface hardness: HRC 56–62, case per duty

Why choose: Highest contact strength and wear, strong bending with right root case

Watch-outs: Distortion; choose vacuum carburizing + gas quench for cleaner surfaces & tighter scatter or atmosphere + oil for broader applicability

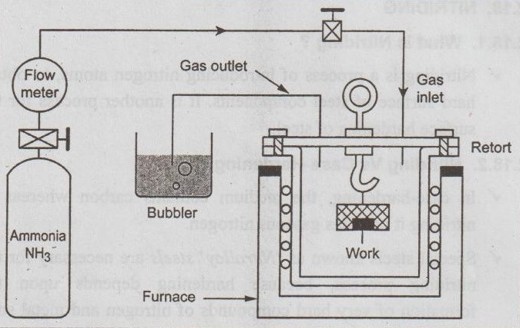

3.3 Nitriding

Steels: 38CrMoAl, select Cr-Mo / Ni-Cr-Mo grades

Surface hardness: HRC ≥65 (often specified in HV); very low distortion

Why choose: Finish-first geometry, thin hard case with excellent wear & fatigue limits

Watch-outs: Thinner case than carburized; control compound layer to avoid brittleness

3.4 Quench & Temper (Q&T)

teels: 45 / 1045, 40Cr / 5140

Tooth hardness: ~HB 200–280 (HRC low-mid 30s if converted)

Why choose: Simple, fast, economical; easy finishing

Watch-outs: Lower flank hardness—check contact stress and lubricant

3.5 Normalizing

Outcome: HB 160–220, refined grains, stress relief

Why choose: Better machinability, steadier response in downstream hardening

Watch-outs: As-normalized gears suit lower mechanical strength unless followed by hardening

4.Reference

Below are illustrative defaults PairGears often recommends. Your drawing, size, module, and volume will tune the details.

4.1 Agricultural Machinery (tractors, harvesters, PTO gearboxes)

Duty reality: Long hours, dirt, shock loading, seasonal peaks; NVH matters but rugged uptime dominates.

Preferred routes:

A: Surface quenching on medium-carbon steels for PTO straight/spiral bevels and spur/helical stages that see moderate impact—hard flanks, tough cores, short cycles.

B: Carburizing + quench for primary torque paths in right-angle boxes or high-load final drives—best contact life under shock and misalignment.

Why: Surface quench is efficient for localized hardening; carburized cases carry heavy loads with durable contact.

Finishing & QA: Grind critical fits; pattern check for bevel pairs; verify profile/lead/pitch on high-ratio stages.

Tip: In dusty service, consider a slightly thicker case and an anti-scuff additive pack in oil.

4.2 Trucks (on/off-highway; differentials, power dividers, auxiliaries)

Duty reality: High torque, high mileage, strict pass-by/cabin NVH; rebuild economics matter.

Preferred routes:

A: Carburizing + quench + temper on ring & pinion and high-load gearsets (often vacuum carburizing + gas quench for lower scatter and cleaner surfaces).

B: Nitriding for precision auxiliaries with tight geometry that shouldn’t move after finish-machining (e.g., light-duty transfer gearsets, sensor-indexed wheels).

Why: Carburized cases deliver the best contact & bending strength; gas quench narrows distortion spread for quiet highway whine. Nitriding keeps geometry locked with excellent wear.

Finishing & QA: Hard-grind flanks and roots; optional superfinish for premium quietness; provide Eht and microhardness traverses in PPAP.

4.3 Construction Equipment (cranes, excavators, winches, slewing drives)

Duty reality: Transient peaks, shock, bidirectional duty; field serviceability and robustness first.

Preferred routes:

A: Carburizing + quench for slewing/rotation bevel stages and high-torque reducers—deep case and tough core absorb shocks.

B: Surface quenching for large-module spur/helical stages where localized hardening is practical and fast.

C: Q&T for cost-sensitive auxiliary gears with modest duty; normalize as a pre-treat for stable machining.

Why: Construction cycles punish flanks and roots; deep cases and robust cores prevent micro-pitting and tooth root failures.

Finishing & QA: Balance grind stock for distortion; document contact patterns at spec mounting distance.

4.4 Electric Vehicles (e-axles, differentials, high-speed angle stages)

Duty reality: High rpm, continuous torque, no engine masking—gearbox acoustics are exposed.

Preferred routes:

A: Vacuum carburizing (LPC) + gas quench + temper for bevel and helical sets—clean surfaces, tighter distortion band, less grind variability,lower gear whine.

B: Nitriding for precision timing trains or light-load stages where minimal movement and high surface hardness matter.

Why: EVs demand the quietest flanks at high rpm; LPC + gas quench routinely delivers the best NVH repeatability.

Finishing & QA: Hard-grind; superfinish optional for cabin-quiet targets; verify profile/lead micro-geometry (crowning/bias) for noise stability.

5.Cross-Route Comparison

| Attribute | Surface Quench | Carburize + Quench | Nitriding | Q&T | Normalizing |

| Surface hardness | HRC 45–50† | HRC 56–62 | HRC ≥65 (HV spec common) | HB 200–280 | HB 160–220 |

Case depth | Shallow/local | Tunable (deep) | Thin | Through | N/A |

Core toughness | High | High | High (unchanged) | Medium | Medium |

| Distortion | Low–Medium | Medium (min with LPC+gas) | Very low | Low | Low |

| NVH potential | Good | Excellent (post-grind) | Excellent | Fair | Fair |

Typical use | Ag PTO, mid-duty | Trucks, EVs, heavy stages | Precision, finish-first | Cost-sensitive, modest duty | Pre-treat/low-strength

|

6.Selecting the route: five practical questions

What's the duty map? Continuous vs. peak torque/speed defines case depth, hardness, and micro-geometry.

How strict is NVH? The tighter the noise window, the more you’ll favor carburized + hard grind (+/- superfinish) or nitriding with minimal movement.

What moves in heat? Slender parts and thin webs steer you toward LPC + gas quench or nitriding to reduce scatter.

What's the finish plan? Nitriding likes finish-first; carburizing expects grind; surface quench depends on the coil path and your stock plan.

What's the value equation? Consider not just furnace time but scrap/rework risk, post-grind time, and NVH audits.

7.Example build recipes

Ag PTO bevel stage (medium impact): 40Cr (5140) → induction harden flanks & root → temper → grind fits & verify pattern → robust EP oil.

Truck differential ring & pinion: Low-alloy case-hardening steel → LPC + gas quench + temper → hard-grind flanks & root → optional superfinish → NVH audit at speed.

Excavator slewing drive: Case-hardening steel → carburize + oil/gas quench (section-dependent) → temper → grind → pattern check; slightly thicker case for shock loads.

EV e-axle bevel set: Case-hardening steel → LPC + gas quench + temper → hard-grind → micro-geometry validation (profile/lead charts) → superfinish if cabin-quiet target.

8.Quality artifacts you should see in every part

Geometry through heat: Runout, concentricity, helix & profile held within spec before/after hardening.

Tooth accuracy: Reported profile/lead/pitch with charts.

Case integrity (if applicable): Effective case depth (Eht), surface carbon, microhardness traverse, retained austenite (as required).

Functional checks: Light-load contact patterns and backlash windows at design mounting distance.

Traceability: Steel heats, furnace loads, quench media, finishing recipes—locked for repeatability.

9.Conclusion

There's no single "best" heat-treatment for every gear—only the best fit for your duty, NVH goals, geometry, and budget. In agriculture, induction hardening and case hardening both shine; in trucks and EVs, carburizing (often LPC + gas) sets the pace for quiet strength; in construction, deep cases and tough cores tame shock; and in precision assemblies, nitriding protects geometry while boosting wear.

Have a print or target case depth? Let's choose the route, quench, and finishing stack that gets you into production with confidence. Contact us.