Smarter Gear Materials for Green Manufacturing

- Share

- publisher

- Jessica

- Issue Time

- Oct 21,2025

Summary

PairGears Guide explanation how material choice and greener processes—dry/MQL hobbing, coatings, PM, polymers—boost gear life, NVH, and sustainability.

1.Introduction

At PairGears, we build drivetrain gearsets for agricultural machinery, heavy trucks, construction equipment, and EVs. As a precision gear manufacturer and custom gear supplier, we're seeing two forces converge: customers want longer life and lower NVH, and they also want greener manufacturing-less energy, fewer consumables, cleaner shop floors. This article translates current research and shop-floor practice into choices you can use: from forging vs. extrusion/rolling and anti-burn grinding to dry/MQL hobbing, tool coatings, powder metallurgy (PM), and engineering polymers (including coated plastic gears). We’ll also map materials and processes to PairGears' four sectors so you can pick a route that hits performance and sustainability.

2.Why the Material–Process Pair Matters

A gear's flank must survive rolling + sliding contact, while the root handles bending. You want a hard, wear-resistant surface and a tough core, delivered by a route that doesn't blow up distortion, cost, or CO₂. The material–process pair determines:

Life: pitting/scuffing resistance (surface) and bending fatigue (core).

Noise (NVH): stable microgeometry through heat treat and finishing.

Throughput & cost: fewer steps, less scrap/rework.

Sustainability: oil and energy use, coolant burden, waste stream.

3.Forming & Finishing: Faster, Cleaner, More Consistent

3.1 Near-Net Forming (Forward/Transverse Extrusion, Rolling)

Researchers and tier suppliers have shown that controlled metal flow during forward or transverse extrusion and rolling can raise core strength and reduce machining stock. The payoff is lower energy per part and more stable tooth roots—especially valuable on helical gears with small tooth counts and large helix angles where profile control is touchy. In practice, we pair these routes with normalize/Q&T pre-treats to tame residual stresses before cutting or finishing.

3.2 Grinding Without Burn (High Productivity, Low Damage)

On hardened gears, grinding burn silently nukes life. Modern lines optimize stock distribution (rough/finish splits), wheel specs, infeed, and coolant to keep heat down. Barkhausen noise and nital etch are common shop tests; we add profile/lead charts and roughness audits so what looks good also runs quiet.

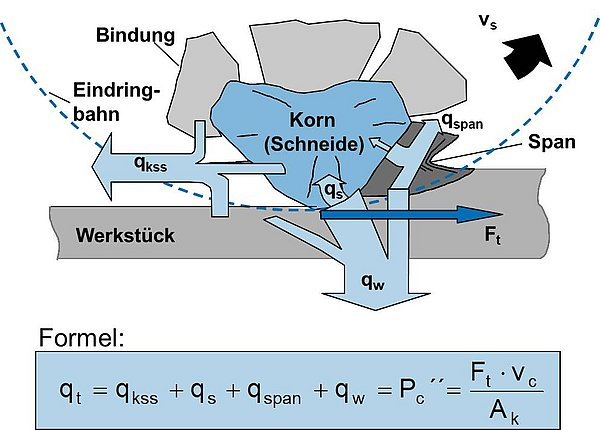

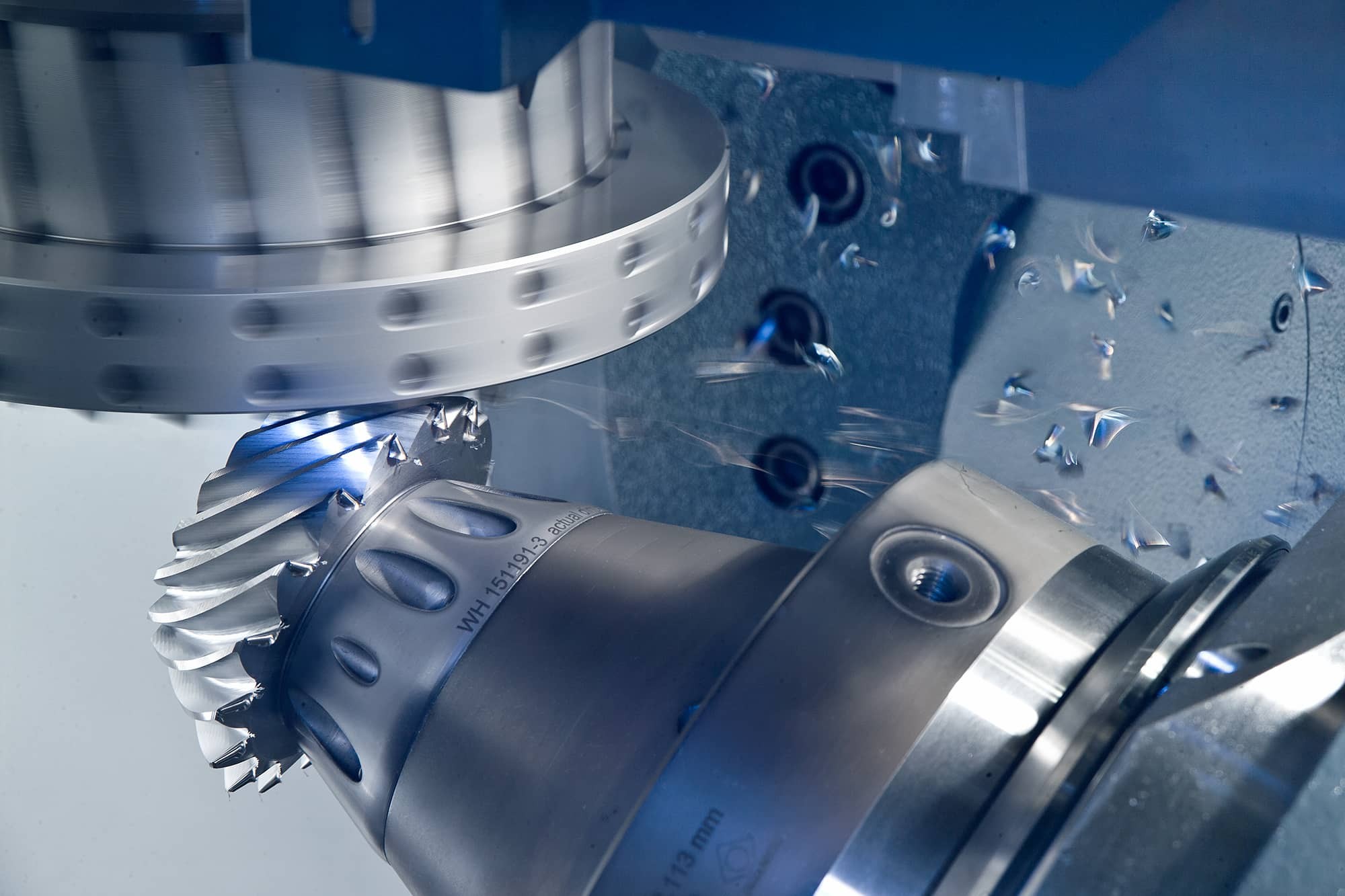

4.Cutting with Less Oil: Dry Hobbing, MQL, and Smarter Fluids

4.1 Dry & MQL Hobbing

Dry hobbing removes flood coolant entirely; MQL (Minimum Quantity Lubrication) sprays a tiny, targeted mist. Success depends on hob coatings (TiN, TiCN, TiAlN, TiSiN families), edge prep, chip evacuation, and a rigid machine. Trials show MQL often hits the sweet spot for tool life vs. oil burden, especially on alloy steels.

4.2 Beyond Mineral Oil: Water-Based & Specialty Oils

New water-based lubricants and low-sulfur, high-wettability oils can cut smoke and waste while keeping flank finish in spec. Chemistry matters: activity, oxidation behavior on the tool, and wetting decide whether you see built-up edge or clean shearing.

(Pro tip: whichever path you choose, log tool life vs. Ra/Rz and keep a coolant audit—concentration, contaminants, flow.)

5.Materials: From Forged Steels to PM and Polymers

5.1 Forged & Rolled Steels (the benchmark)

Where they win: high load, long life, tight NVH windows.

Typical routes: low-carbon case-hardening steels + carburize & quench (then hard-grind, optional superfinish), or medium-carbon steels + induction for localized hardening.

Why we still love them: best contact + bending strength and widest playbook of heat-treat options (including low-distortion vacuum carburizing + gas quench for EVs and premium trucks).

5.2 Powder Metallurgy Gears

Why consider PM: near-net shapes, low scrap, consistent porosity—great for cost, material yield, and sustainability.

Trade-offs: baseline performance trails forged steel until you raise surface density and deepen hard layers (infiltration, selective densification, surface hardening).

Where they fit: moderate loads, compact reducers, and high-volume parts where material efficiency is a win.

5.3 Plastics & Polymers (POM/Acetal, PA/Nylon, PEEK)

Why consider polymers: low noise, low inertia, corrosion immunity; can run dry/grease with proper design.

Modeling matters: polymer gears move with temperature and humidity; use load-sharing and transmission-error models that include environment and speed.

Steel–plastic vs. plastic–plastic pairs: tests often show plastic–plastic pairs run smoother (lower TE ripple) than steel–plastic, if both are the same resin and properly designed.

High-temp PEEK: expands the load/speed envelope; commonly chosen for quiet, efficient drives with weight targets.

Surface engineering: DLC on POM or similar thin-film coatings can boost wear life dramatically at modest cost.

6.Coatings & Tools: Small Layers, Big Gains

Hob coatings (TiN/TiCN/TiAlN/TiSiN): extend tool life in dry/MQL, resist crater wear, and stabilize roughness.

DLC on polymers: improves wear and reduces friction; watch temperature to protect the substrate.

Wheel specs & dressing: pick structures and dress parameters that remove heat; more porosity ≠ less control—validate with Barkhausen.

7.How We Match Choices to PairGears

7.1 Agricultural Machinery

Reality: mud, shock loads, long hours; serviceable gearboxes.

Material–process picks: forged case-hardening steels for primaries (carburize + quench + grind), induction on large-module auxiliaries, and PM where loads allow. MQL hobbing often works well; EP oils must tolerate contamination.

Why: deep cases + tough cores absorb field shocks; greener cutting reduces waste without risking life.

7.2 Heavy Trucks

Reality: long mileage and strict NVH.

Material–process picks: vacuum carburizing + gas quench for ring/pinion; hard grind + optional superfinish; MQL or optimized wet hobbing with coated hobs.

Why: low-scatter distortion and refined flanks keep whine down over millions of cycles.

7.3 Construction Equipment

Reality: transient peaks, dust, and bidirectional duty.

Material–process picks: forged steels with carburized deep cases for slewing/winch stages; induction for big spurs; robust grinding anti-burn control.

Why: surface integrity and root toughness trump everything; dry/MQL helps but rigidity and cooling are non-negotiable.

7.4 Electric Vehicles (EVs)

Material–process picks: low-distortion vacuum carburizing + gas quench, tight microgeometry control (profile/lead crowning and bias), superfinish where cabin targets demand it. Dry/MQL feasible with the right coatings and machine envelope.

Why: micro-NVH stability decides customer perception; greener processes are welcome if they don’t move the geometry.

8.Quick Selection Matrix

| Goal | Good Choices | Watch-outs |

| Highest life & lowest NVH | Forged case-hardening steel + carburize/quench + grind | Distortion control; grind burn |

| Material efficiency & cost | PM (sintered) with surface densification/hardening | Core density & case depth limits |

| Quiet + light + corrosion-free | POM/PA/PEEK polymers; consider DLC | Temperature/humidity, tooth form, bearing stiffness |

Less oil, cleaner floor | MQL or dry hobbing + Ti-based hob coatings | Machine rigidity, chip flow, edge prep |

Anti-burn finishing | Optimized stock split, wheel spec, coolant + Barkhausen | Don't trade burn for waviness—check profile/lead |

9.Practical QA & Verification

Tooth-form charts (profile/lead/pitch) for microgeometry and NVH stability.

Hardness & case depth: surface hardness and Eht for case-hardened parts; microhardness traverses for nitrided/coated cases.

No-burn proof: Barkhausen/nital checks, plus roughness trends.

Geometry through heat: runout, concentricity, helix error—before/after HT.

Functional evidence: light-load contact patterns, backlash at mounting distance.

Traceability: material heats, tool/coating life, coolant audits, furnace loads/recipes, finishing parameters.

External reading (optional): AGMA & ISO gear accuracy/strength frameworks, ASM heat treat references, and tribology texts on dry/MQL machining and plastic gear design.

10.Example Build Recipes

PTO helical gear (mid-duty): forged low-alloy → carburize + quench + temper → hard grind → EP oil tolerant to dirt → MQL hobbing on next rev to cut coolant burden.

Truck differential ring & pinion: vacuum carburize + gas quench → hard grind → superfinish (premium) → NVH audit; coated hobs under MQL for green cutting.

Excavator slewing stage: forged case-hardening steel → deep case carburize → grind with anti-burn window → Barkhausen check; induction route on large spurs where suitable.

EV e-axle helical set: vacuum carburize + gas quench → grind → microgeometry validation (profile/lead) → superfinish for cabin quiet; dry/MQL feasible with TiSiN hobs and rigid setup.

Automation polymer gear pair (POM-POM or PEEK-PEEK): model temperature/humidity; consider DLC on POM; verify transmission error and load-sharing; design bearings for stiffness.

11.Conclusion

Green manufacturing and top-tier gear performance aren't opposites-they're design variables. Pick the material-process pair that serves the duty: forged and case-hardened steels for the highest loads and quietest drives; PM when yield and cost dominate; polymers where low noise and mass matter; and surround them with dry/MQL cutting, smart coatings, and anti-burn finishing. Do that-and verify with disciplined QA-and you'll get long life, low NVH, lower oil use, and cleaner throughput across agriculture, trucks, construction, and EVs.

Have a print or target spec? We'll help you choose the material + process + QA stack that fits your goals—and your sustainability targets.Contact us.