Introduction to Planetary Gears and Their Applications

- Share

- publisher

- pairgears

- Issue Time

- Oct 24,2024

Summary

Planetary gears are efficient, compact, and widely used. This article highlights their principles, benefits, and PairGears' expertise in agriculture, construction, and EV applications.

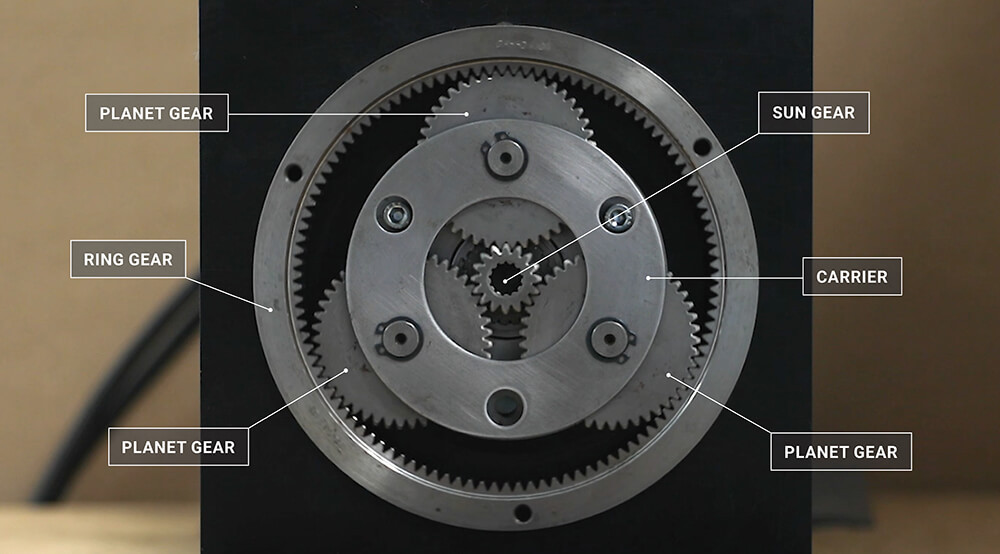

Understanding Planetary Gears: Structure and Operation

A planetary gear system consists of a central sun gear, surrounded by one or more planet gears that are held in place by a rotating carrier and mesh with an outer ring, or annulus. The structure is compact, allowing for higher torque in smaller spaces and enabling efficient transmission in complex machinery.

• Sun Gear: The central gear, receiving power directly from the motor or input shaft.

• Planet Gears: Surround the sun gear, distribute load evenly, and rotate around it.

• Planet Carrier: Holds the planet gears and transfers the combined rotational force.

• Ring Gear (Annulus): Encircles the planet gears, providing additional stability and torque.

Advantages of Planetary Gears

Planetary gears offer several key benefits over other gear types:

• High Torque Density: The design allows high torque output within a compact structure.

• Efficiency: Planetary systems reduce losses, which is essential for applications requiring consistent power.

• Load Distribution: With multiple points of contact, the load is evenly distributed across planet gears, minimizing wear.

• Versatility: Suitable for applications where space and weight are constraints, such as in robotics and aerospace.

PairGears focuses on delivering high-precision planetary gears that withstand high stress and heavy-duty usage, aligning with our commitment to quality and durability.

Applications of Planetary Gears

Agricultural Machinery

Planetary gear systems are used in tractors and harvesters, where robust torque and precise control are essential. PairGears provides gears that meet the rigorous demands of agricultural machinery, enabling reliable power transfer across a variety of challenging terrains.

Construction Equipment

In construction vehicles like excavators, planetary gears drive the tracks and other heavy components. Their durability and strength make them ideal for high-stress environments. Our construction machinery gears at PairGears deliver dependable performance, even in extreme conditions.

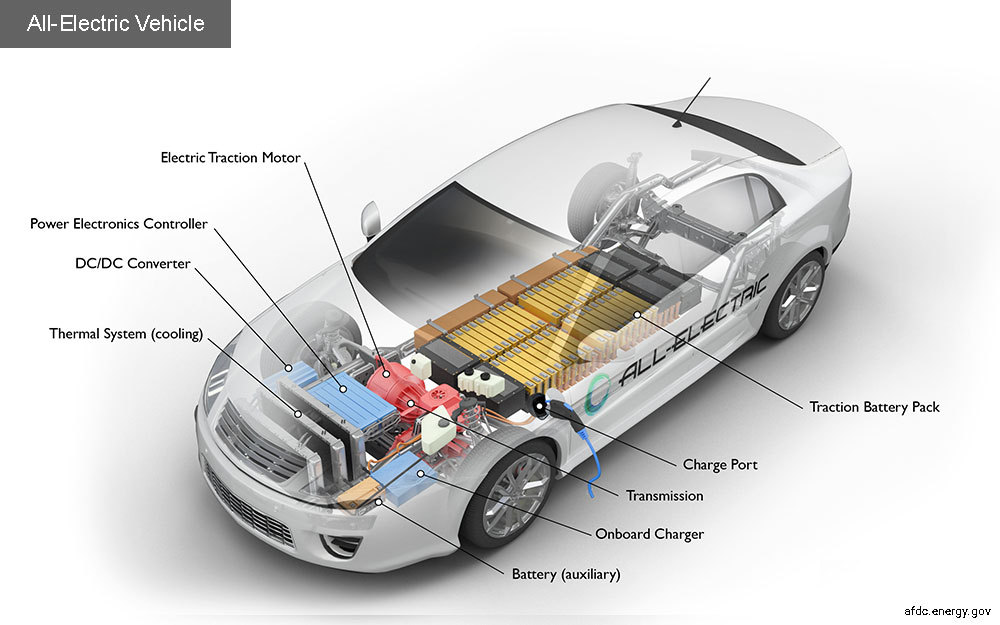

Electric Vehicles (EVs)

As EVs become more prevalent, planetary gear systems have become essential in electric motors and regenerative braking systems. The compact design of planetary gears helps reduce weight, improving battery life and overall efficiency. PairGears specializes in customized solutions for EV applications, ensuring precision and efficiency.

Robotics and Automation

In robotic systems, planetary gears help in achieving smooth, controlled motion. Their small size and ability to deliver high torque make them ideal for robot arms and precise equipment. PairGears provides high-quality, specialized gears tailored for automation needs.

Future Innovations with Planetary Gears

With advancements in materials and precision engineering, the capabilities of planetary gear systems are evolving. Smart materials and AI-powered gear design are opening up new possibilities, promising greater durability and efficiency.

Why Choose PairGears for Your Planetary Gear Needs?

At PairGears, we pride ourselves on offering customized planetary gears tailored to specific applications in agriculture, construction, electric vehicles, and beyond. Our focus on precision engineering and durability ensures that each product can withstand rigorous use and deliver consistent performance., For more detailed information on how our planetary gears can serve your specific industry needs, visit PairGears solutions page.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.