How to Choose the Right Gear Type?

- Share

- publisher

- pairgears

- Issue Time

- Jun 21,2024

Summary

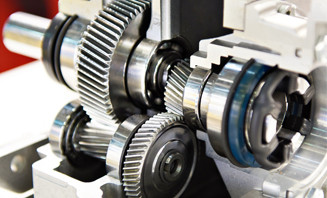

Choosing the right gear type is key to optimal machinery performance. This guide covers various gears, their uses, and how to select the best one for your needs.

What Exactly Is a Gear?

Gears are essential components in mechanical systems, used to transmit motion and torque between machine parts. Selecting the right gear type is critical to ensure the efficiency, durability, and performance of your machinery. This article will explore various types of gears, their characteristics, and how to choose the most suitable gear for your needs.

Types of Gears

1.Spur Gears

• Description: Spur gears have straight teeth and are mounted on parallel shafts.

• Applications: Clocks, washing machines, convey or systems.

• Advantages: Simple design, easy to manufacture, efficient at high speeds.

• Disadvantages: Noisy at high speeds due to abrupt engagement of teeth.

2.Helical Gears

• Description: Helical gears have teeth that are cut at an angle to the gear axis, forming a helix.

• Applications: Automotive transmissions, elevators, conveyors.

• Advantages: Quieter and smoother operation compared to spur gears.

• Disadvantages: Produce axial thrust and are more complex to design and manufacture.

3.Beval Gears

• Description: Bevel gears have teeth that are cut on a conical surface, allowing them to transmit motion between intersecting shafts.

• Applications: Differential drives, hand drills, marine applications.

• Advantages: Capable of changing the direction of motion and power flow.

4.Worm Gears

• Description: Worm gears consist of a worm (screw) and a worm wheel (gear), providing high reduction ratios.

• Applications: Elevators, conveyor belts, tuning instruments.

• Advantages: High reduction ratios, self-locking capability.

• Disadvantages: Lower efficiency due to high friction, heat generation.

How to Choose the Right Gear Type

1.Understand the Application Requirements:

Consider load, speed, and operating conditions.

2.Evaluate Gear Efficiency:

Higher efficiency gears reduce energy loss and heat generation.

3.Consider Noise Levels:

Helical gears are quieter than spur gears.

4.Analyze Space Constraints:

Bevel and worm gears can help in compact designs.

5.Maintenance Needs:

Choose gears that match your maintenance capabilities and schedules.

Conclusion

Selecting the right gear type is essential for ensuring the longevity and performance of your mechanical systems. By understanding the different gear types and their specific applications, you can make an informed decision that best suits your needs. For more detailed information and customized solutions, visit our website at PairGears.