How to Calculate Gear Module: A Step-by-Step Guide

- Share

- publisher

- pairgears

- Issue Time

- Nov 20,2024

Summary

Gear modules are key in mechanical design. Learn calculations, significance, applications, and how PairGears delivers precise modules for various industries.

Introduction to Gear Module

The gear module is a fundamental parameter in gear design, determining the size relationship between the gear's pitch diameter and the number of teeth. It plays a crucial role in ensuring compatibility and optimal performance in gear pairs. This guide offers a clear methodology for calculating the module, enhancing your understanding of its application in mechanical systems.

What is Gear Module?

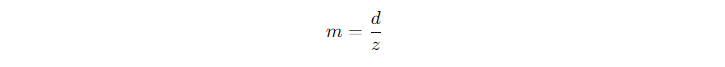

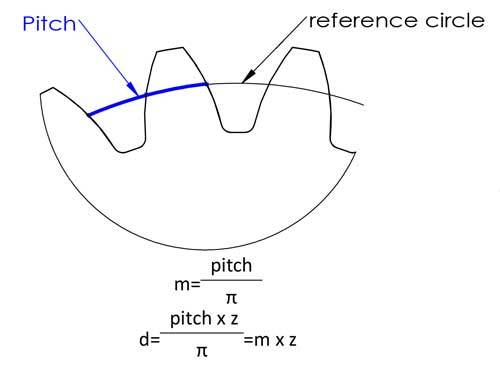

The gear module (m) is defined as:

Where:

m = Gear module (in mm)

d = Pitch diameter of the gear (in mm)

z = Number of teeth on the gear

The module reflects the standard tooth size, influencing the gear's strength, precision, and compatibility.

Why is Gear Module Important?

1. Standardization: Ensures gears can be interchanged globally when using standard modules.

2. Strength and Durability: A higher module typically means thicker, stronger teeth suitable for heavy loads.

3.Precision: Accurate module calculation ensures smooth gear meshing, minimizing wear and vibration.

PairGears produces gears with precise modules for applications like agricultural machinery, trucks, and industrial equipment. Check our gear products to explore high-quality options.

Step-by-Step Guide to Calculate Gear Module

1. Measure the Pitch Diameter (d):

· Use calipers to measure the gear's diameter across its teeth.

· Example: If d=50 mm.

2. Count the Number of Teeth (z):

· Physically count the teeth or refer to design specifications.

· Example: z=20.

3. Apply the Formula:

· Using m=d/z, substitute the values.

· Calculation: m=50/20=2.5 mm.

4. Validate the Results:

· Cross-check with industry standards to ensure compatibility.

For a detailed tutorial, watch a video below.

Common Gear Module Standards

Gear modules are often standardized according to ISO or AGMA. Common modules include 1, 1.5, 2, 2.5, and 3 mm. Selecting the appropriate module depends on the application’s load, precision, and speed requirements.

Conclusion

Accurate calculation of the gear module is a cornerstone of effective gear design. Whether you're developing systems for heavy-duty vehicles or precision equipment, understanding this concept ensures optimal performance and longevity. Visit PairGears for a wide range of gears designed to meet diverse industrial needs.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.