Helical Gears vs. Spur Gears: Key Differences and Applications

- Share

- publisher

- pairgears

- Issue Time

- Oct 18,2024

Summary

Helical and spur gears have unique structural differences suited to distinct applications. This article compares their strengths and helps in choosing the right gear for specific needs.

Introduction

In mechanical engineering, selecting the right type of gear is essential to optimizing system performance. Helical gears and spur gears are among the most commonly used gears, each serving specific functions. While they both transmit power and motion, they have distinct characteristics. In this article, we’ll explore the primary differences between helical and spur gears, their applications, and how each type aligns with the needs of various industries, including agriculture, automotive, and heavy machinery.

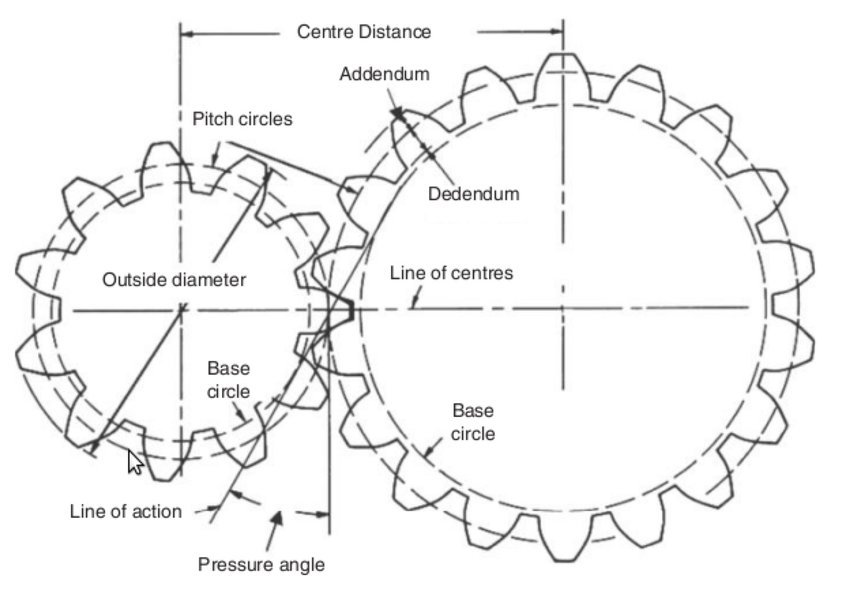

1. Structural Differences

Helical Gears

Helical gears are designed with angled teeth that spiral around the gear shaft. This angled design provides a smoother, quieter operation, as multiple teeth are engaged simultaneously. This feature minimizes vibration and makes helical gears ideal for high-speed applications.

Pairgears has a wide selection of high quality helical gears.

Supports universal OEM codes for agricultural vehicle Gear R256357

Supports universal OEM codes for ZF gearbox gear ZF Gearbox Gear 93191184, 1295197, 81323010992, 81323020071, 5001848791......

Supports universal OEM codes for agricultural vehicle Gear R278371

Supports universal OEM codes for VW truck gear 4301529, R02511, 10330543, 12549632, 2RG311441, 6007004177001, 7149553, A0012620512.

Spur Gears

Spur gears, on the other hand, have teeth that are parallel to the gear’s axis. They are simpler in design, which makes them more economical and easy to produce. However, due to their direct tooth-to-tooth contact, spur gears are generally louder and more prone to wear at high speeds.

Example Application: PairGears Spur Gears are ideal for applications where noise levels are not a primary concern, such as in industrial machinery and agricultural equipment.

Supports universal OEM codes for Massey Ferguson agricultural vehicle gear 964916M1

Supports universal OEM codes for JOHN DEERE agricultural vehicle gear L113164

Supports universal OEM codes for tractor gears 3346866, 3316672, 80796610, 80796600

Supports universal OEM codes for agricultural vehicle gear 81884C1, 9968080, K395114

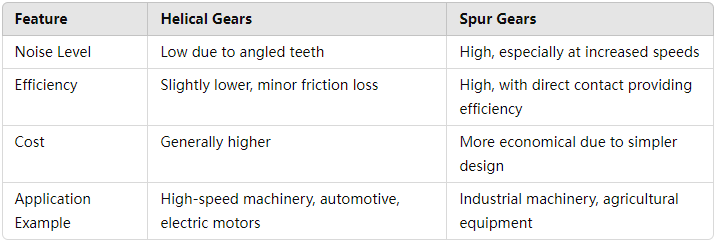

2. Efficiency and Noise Levels

Noise

One of the most notable differences is noise. Helical gears, with their angled teeth, distribute load more evenly, resulting in less noise. Spur gears, while efficient, tend to generate more noise at high speeds, making them suitable for applications where quiet operation is not essential.

Efficiency Comparison

Both types of gears are efficient at power transmission, but helical gears tend to be slightly less efficient due to increased friction from the angled teeth. This friction can lead to a minor efficiency loss but is usually outweighed by the benefits in noise reduction and smooth operation.

3. Applications in Different Industries

Agricultural Machinery

In agriculture, gear durability and reliability are paramount. Helical gears are often used in tractors and harvesters where smooth motion is necessary for consistent fieldwork. Conversely, spur gears find their place in machinery that requires direct and straightforward power transmission.

See More: Our selection of tractor gears and shafts includes both spur and helical gears suited for various farming equipment.

Automotive and Heavy-Duty Vehicles

For vehicles requiring quiet and efficient power transmission, such as in trucks and electric vehicles, helical gears are favored. Their smooth motion is essential for comfortable and efficient vehicle operation. For instance, PairGears truck gears are designed to meet these demands, providing durability and noise reduction.

Industrial Machinery

In high-torque applications, spur gears excel due to their straightforward design, providing an efficient solution where noise is less of a concern. For example, mining equipment often employs spur gears for their strength and ability to withstand substantial loads.

4. Cost and Maintenance

Spur gears are generally more affordable than helical gears, given their simpler manufacturing process. Additionally, they are easier to maintain, as they lack the complex angle of helical gears, reducing potential alignment issues.

5. Performance Comparison Table

Conclusion

Understanding the differences between helical and spur gears enables informed decisions in gear selection. At PairGears, we offer a comprehensive range of both helical gears and spur gears designed to meet the demands of various applications. Whether your focus is on efficiency, noise reduction, or cost-effectiveness, we have the right solution for you.

For further insights, explore YouTube video on Helical vs. Spur Gears to see these gears in action and understand their real-world applications, if you're interested, subscribe to our YouTube channel, where we share a few videos of gears in action every week.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.