Gear Profile: Learn all about Involute and Cycloidal Gear Profiles

- Share

- publisher

- pairgears

- Issue Time

- Oct 18,2024

Summary

This blog explores involute and cycloidal gears and their applications in agricultural machinery and construction equipment, emphasizing their importance for efficiency.

Introduction

Gears are fundamental components in machinery, facilitating the transfer of motion and power. Among the various gear profiles, involute and cycloidal gears are the most commonly used. This article delves into the characteristics of these two profiles, helping you make informed decisions when choosing gears for your applications. If you're interested in our high-quality gear solutions, visit our website at PairGears.

Involute Gear Profile

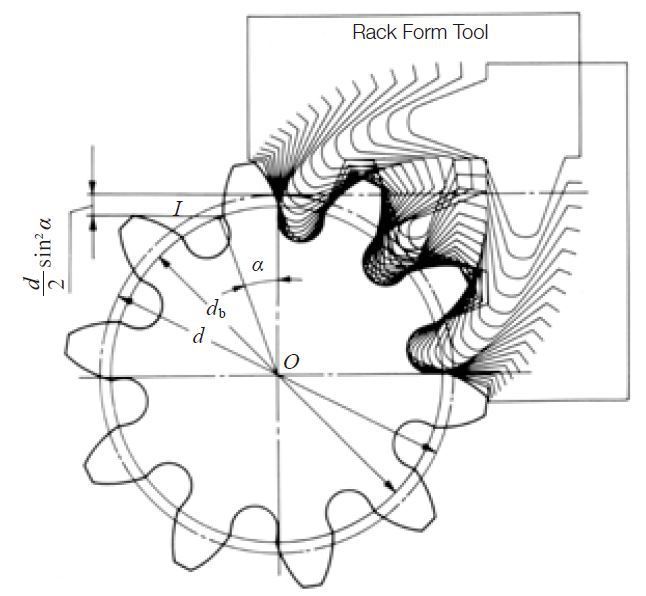

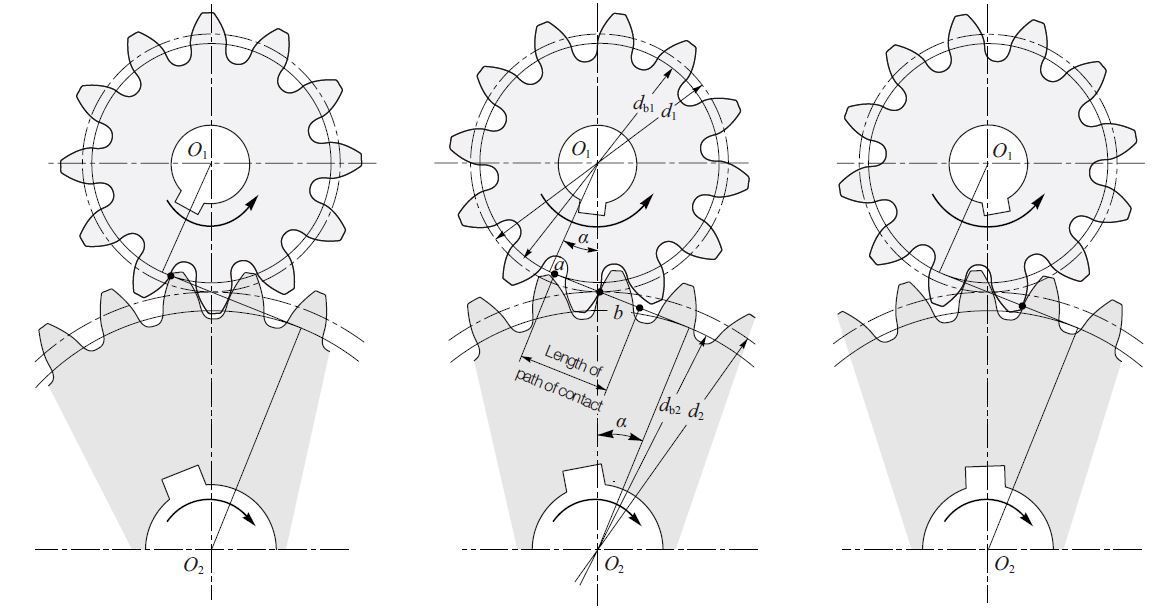

Definition and Geometry

The involute gear profile is defined by its unique shape, which is generated by unwinding a string from a base circle. The involute curve ensures constant velocity ratio and smooth operation, making it ideal for most applications.

Advantages of Involute Gears

1、Self-Alignment: Involute gears maintain proper meshing even with slight axial movements.

2、Efficiency: They provide higher transmission efficiency, reducing energy loss during operation.

3、Durability: The profile distributes load evenly, enhancing the lifespan of gears.

Applications

Involute gears are widely used in various industries, including automotive and agricultural machinery. For instance, our gears at PairGears are designed to meet the demanding requirements of modern tractors and construction equipment,below is an individual demonstration of our involute gears,to learn more about our products, please visit our product page.

Supports universal OEM codes for Massey Ferguson agricultural vehicle gear 964916M1

Supports universal OEM codes for JOHN DEERE agricultural vehicle gear L113164

Supports universal OEM codes for tractor gears 3346866, 3316672, 80796610, 80796600

Supports universal OEM codes for agricultural vehicle Gear 84996901, ZF 0092346033

Cycloidal Gear Profile

Definition and Geometry

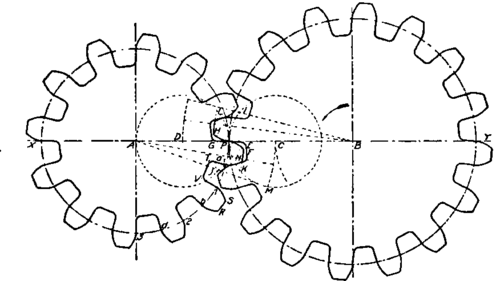

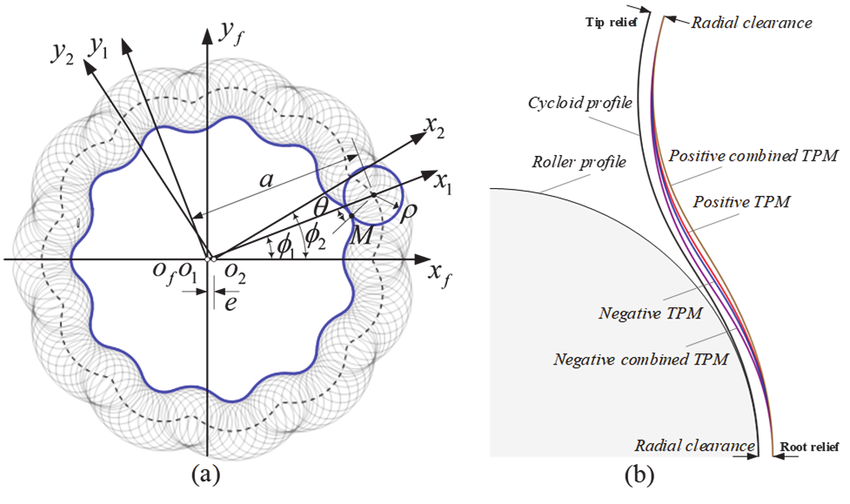

Cycloidal gears differ significantly from involute gears. The tooth shape is derived from the path traced by a point on the circumference of a circle as it rolls along a straight line. This unique geometry provides several distinct characteristics.

Advantages of Cycloidal Gears

1、Compact Design: Cycloidal gears can be designed smaller than their involute counterparts while maintaining similar performance levels.

2、Load Capacity: They can handle higher loads due to the shape of the teeth, making them suitable for heavy-duty applications.

3、Reduced Wear: The rolling motion reduces friction and wear, leading to longer service life.

Applications

Cycloidal gears are often found in applications requiring high torque and compact size, such as in robotics and heavy machinery.

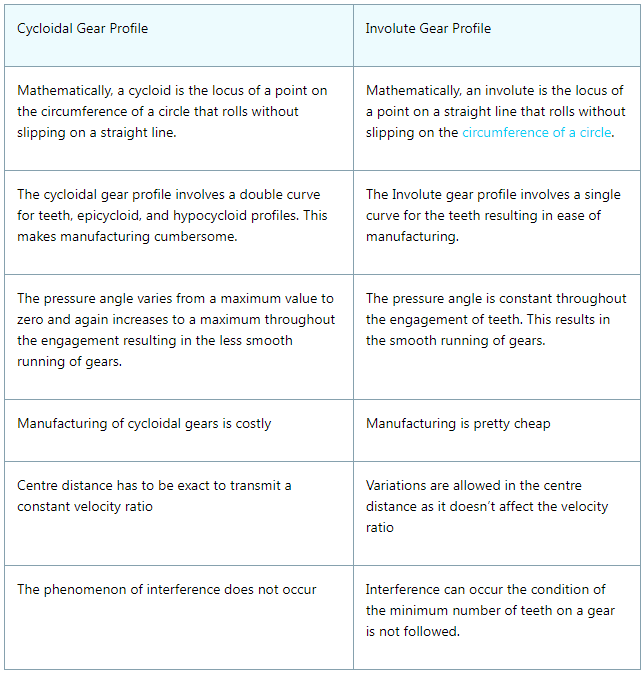

Difference Between Involute and Cycloidal Gear Profile

The differences mentioned here give us an understanding of why Involute profiles are used over Cycloidal profiles. We have laid a comparison of these two profiles side-by-side.

Here's a video to compare the differences, but if you're interested, subscribe to our YouTube channel, where we share a few videos of gears in action every week.

Conclusion

Choosing the right gear profile is crucial for optimizing the performance of your machinery. Involute gears offer excellent efficiency and durability, while cycloidal gears provide compact designs and higher load capacities. At PairGears, we are committed to delivering high-quality gear solutions tailored to meet the specific needs of our customers. For more information on our products and to explore our range of gears, visit PairGears.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.