Exploring the Materials of Worm Gears: Focus on Tin Bronze and Other Materials

- Share

- publisher

- pairgears

- Issue Time

- Feb 5,2025

Summary

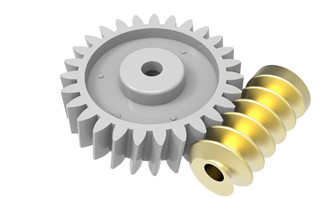

Worm gears, vital for high torque in compact designs, rely on materials like tin bronze for wear resistance. Other options include aluminum bronze, cast iron, and steel, chosen based on application needs.

Worm Gear Materials

At PairGears, we specialize in manufacturing high-quality gears, including precision worm gears used in various industrial applications. Our gears, which are built to the highest standards of quality, are designed to ensure reliable and efficient performance. With a diverse product range and a commitment to excellence, we provide tailored solutions to meet the needs of industries such as agriculture, transportation, and machinery.In this blog, we delve into the materials commonly used for worm gears, focusing primarily on tin bronze, a preferred choice for its unique properties.

Understanding the advantages of different materials is crucial for selecting the right type of worm gear for your mechanical systems, ensuring longevity and optimal performance.

The Role of Material Selection in Worm Gear Performance

Worm gears are widely utilized for their ability to transmit high torque and provide reduction ratios in a compact design. However, choosing the appropriate material for worm gears is key to achieving high performance, durability, and reduced maintenance costs. Factors such as load capacity, environmental conditions, wear resistance, and corrosion resistance all influence material selection.

Some of the most commonly used materials for manufacturing worm gears include tin bronze, aluminum bronze, cast iron, steel, and stainless steel. Each material has distinct characteristics that make it suitable for specific applications.

1. Tin Bronze for Worm Gears: A Durable and Reliable Choice

Tin bronze is one of the most popular materials used for worm gears, especially in applications that require high wear resistance and corrosion resistance. This alloy is made by combining copper with tin, and sometimes small amounts of other elements like phosphorus. The primary benefits of tin bronze include:

Advantages:

• Excellent Wear Resistance: Tin bronze has high resistance to wear and can withstand heavy loads and continuous motion, making it ideal for worm gears that experience frequent use.

• Corrosion Resistance: Tin bronze offers excellent resistance to corrosion, particularly in marine, chemical, and humid environments. It prevents degradation from exposure to moisture and chemicals.

• Self-Lubricating Properties: Tin bronze has self-lubricating properties, reducing the need for external lubrication and contributing to a longer lifespan for the gears.

• High Strength: Tin bronze provides high strength-to-weight ratio, ensuring the durability of the gears while keeping the system compact.

Applications:

Due to its excellent properties, tin bronze is ideal for worm gears in marine equipment, robotics, agricultural machinery, and conveyor systems where durability and corrosion resistance are crucial.

2. Aluminum Bronze for Heavy-Duty Applications

Aluminum bronze, another popular material for worm gears, is an alloy of copper and aluminum. This material is known for its high strength, excellent wear resistance, and outstanding corrosion resistance, especially in harsh environments such as marine applications.

Advantages:

• Higher Strength: Aluminum bronze is stronger than tin bronze, making it suitable for high-load applications.

• Corrosion Resistance: Like tin bronze, aluminum bronze excels in environments where exposure to water and chemicals is a concern.

• Wear Resistance: This material can handle significant wear without degrading, ensuring the gears maintain their functionality for extended periods.

Applications:

Aluminum bronze is often used in marine gearboxes, heavy-duty industrial machinery, and mining equipment, where high strength and resistance to wear and corrosion are needed.

3. Cast Iron for Cost-Effective and Durable Worm Gears

Cast iron is another common material used for worm gears, particularly in cost-effective applications where high strength and wear resistance are necessary but not at the expense of high-end materials like bronze or steel.

Advantages:

• High Hardness: Cast iron is highly resistant to wear, which makes it suitable for low-speed, high-load applications.

• Cost-Effective: Cast iron is relatively inexpensive compared to other materials, making it an economical choice for mass production.

• Good Vibration Damping: Cast iron’s ability to absorb vibrations helps in reducing operational noise, making it ideal for systems that require noise reduction.

Applications:

Cast iron worm gears are widely used in gearing systems, transmission systems, and machine tools, where cost-effectiveness is important but durability cannot be compromised.

4. Steel for High-Strength and Heavy-Duty Performance

Steel is often used for worm gears that require higher load-bearing capacity and toughness. Steel worm gears are typically paired with softer materials such as bronze to create a durable and efficient gear system.

Advantages:

• High Strength: Steel provides outstanding strength, allowing worm gears made from steel to handle very high loads.

• Wear Resistance: When heat-treated, steel can achieve superior wear resistance and hardness, making it a good option for heavy-duty applications.

• Versatility: Steel is highly versatile and can be customized through heat treatment processes to meet specific performance requirements.

Applications:

Steel worm gears are used in automotive transmissions, industrial machinery, heavy equipment, and energy systems, where strength and toughness are critical.

5. Stainless Steel for Corrosive Environments

Stainless steel is another material used for worm gears, particularly in environments prone to corrosion. Stainless steel is known for its exceptional resistance to rust and corrosion, making it suitable for applications that involve harsh chemicals or marine environments.

Advantages:

• Corrosion Resistance: Stainless steel is highly resistant to oxidation, rust, and other forms of corrosion, making it ideal for harsh environments.

• Strength and Durability: Stainless steel offers high strength and resistance to wear and fatigue, ensuring long-lasting performance.

• Easy Maintenance: Its smooth surface and resistance to contamination make stainless steel worm gears easy to maintain and clean.

Applications:

Stainless steel worm gears are commonly used in food processing, pharmaceutical equipment, and marine engineering, where cleanliness and corrosion resistance are essential.

Conclusion: Choosing the Right Material for Worm Gears

Selecting the appropriate material for worm gears is a critical decision that impacts the efficiency, durability, and performance of mechanical systems. While tin bronze is often the preferred choice due to its excellent wear and corrosion resistance, materials like aluminum bronze, cast iron, steel, and stainless steel also offer distinct advantages depending on the application.I have written an article before, describing how to choose the material of the gear, you can click for reference.

At PairGears, we understand the importance of material selection in ensuring the longevity and efficiency of gear systems. Whether you require tin bronze worm gears or need a customized solution for heavy-duty or corrosive environments, our expert team is here to provide high-quality products tailored to your needs.

For more information on our products, please visit our product catalog or contact us directly to discuss your specific requirements.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.