Comprehensive Guide to Custom Internal Gear Services

- Share

- publisher

- PairGears

- Issue Time

- Apr 28,2025

Summary

Explore the advantages, applications, and design process of custom internal gears. Learn why PairGears is your trusted internal gear manufacturer.

1. Introduction

Gears are among the most critical components in modern mechanical systems, ensuring smooth transmission of torque and motion. While spur, helical, and bevel gears are widely recognized, internal gears occupy a unique role in industries that demand compact designs, high torque transfer, and reliable performance.

At PairGears, we specialize as a leading internal gear manufacturer, delivering custom internal gear services that meet the exact needs of our clients. This guide explains what internal gears are, their advantages, applications, and why custom design and manufacturing services are essential for OEMs and industrial users.

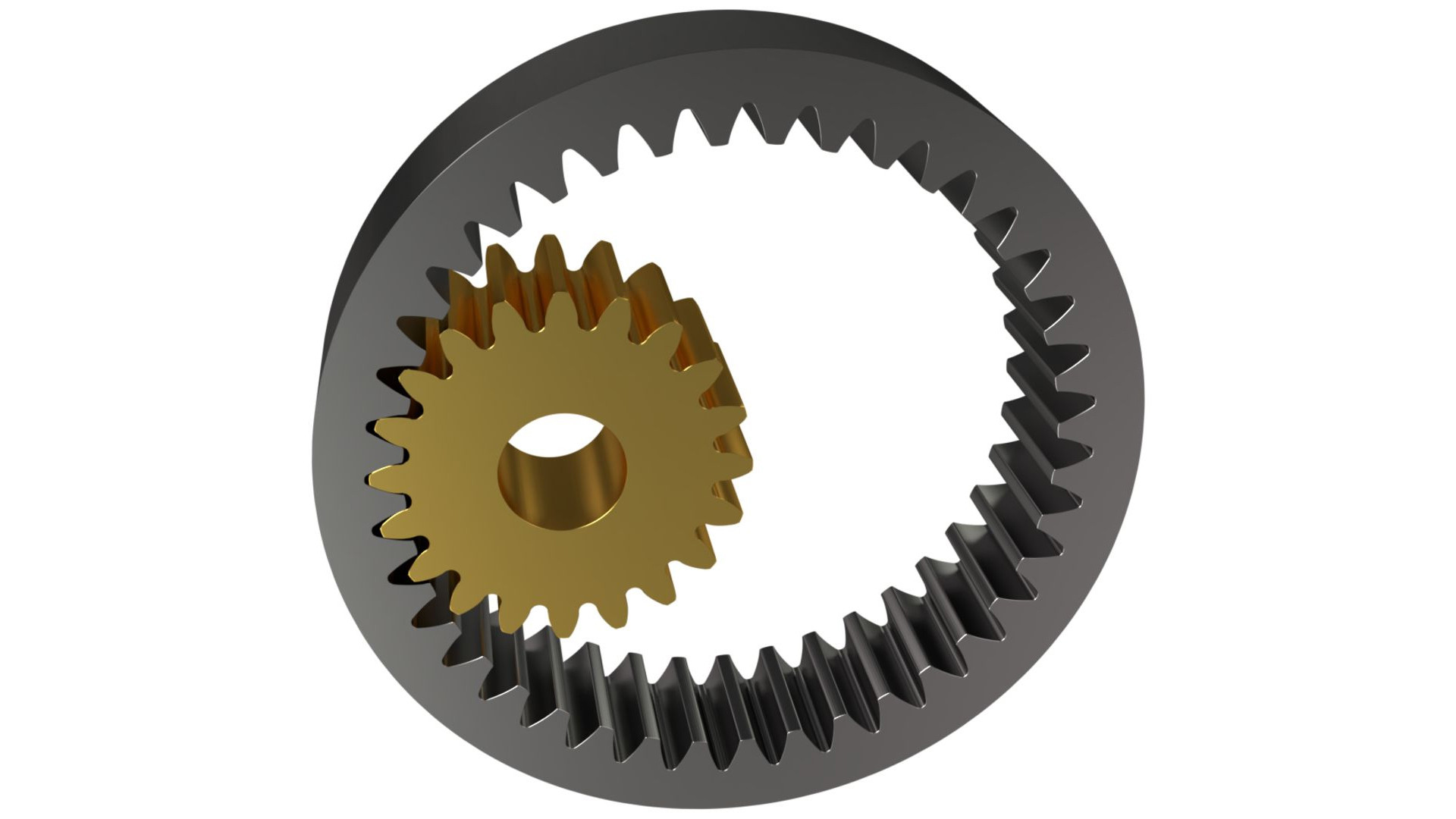

2. What Are Internal Gears?

Internal gears are gears with teeth cut on the inner surface of a cylindrical ring. They mesh with external gears or pinions, transmitting motion and torque inside a compact housing.

Unlike external gears, internal gears allow for parallel and coaxial shaft arrangements, making them indispensable in planetary gear systems, where space optimization and high torque density are critical.

3. Why Choose Custom Internal Gears?

While standard gears may suffice in some machinery, industries often demand custom internal gears for optimal performance. OEMs and engineers request tailored solutions when:

• Off-the-shelf gears do not meet size or torque requirements.

• The application requires specific tooth geometry, module, or pressure angle.

• High durability or unique material properties are needed (e.g., corrosion resistance, lightweight alloys).

• Integration with planetary systems, robotics, or aerospace gearboxes requires non-standard dimensions.

By working with a trusted internal gear supplier, customers ensure their gears are optimized for performance, efficiency, and lifespan.

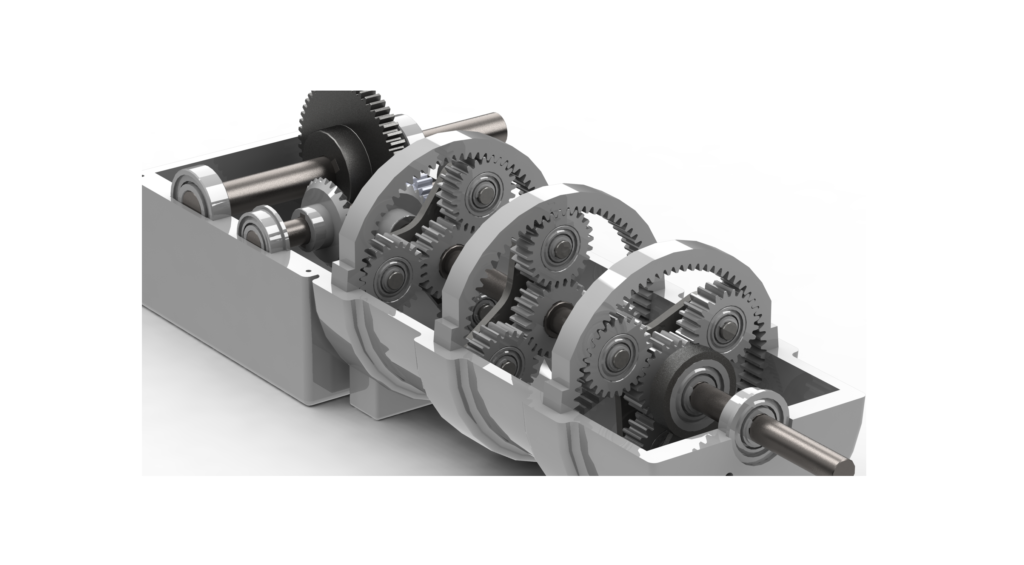

4.1 Compact Design

Internal gears enable more compact gearboxes by allowing the input and output shafts to be closer together. This is critical in robotics, EVs, and aerospace systems.

4.2 High Torque Capacity

Their geometry allows for efficient torque transfer in confined spaces, making them ideal for planetary systems in heavy-duty trucks and wind turbines.

4.3 Customization Flexibility

Tailored modules, bore sizes, and coatings ensure compatibility with unique requirements.

4.4 Noise Reduction

Properly designed internal gears reduce vibration and operational noise, improving user comfort and reliability.

4.5 Durability

With advanced materials (e.g., 20CrMnTi, stainless steel) and treatments like carburizing or nitriding, internal gears achieve exceptional wear resistance.

At PairGears, we provide end-to-end services as a custom internal gear manufacturer:

5.1 Personalized Design

Our engineering team collaborates with OEMs to define tooth profile, module, pressure angle, and bore size for optimal performance.

5.2 Material Selection

We offer carbon steel, alloy steel, stainless steel, and bronze depending on performance requirements — from strength to corrosion resistance.

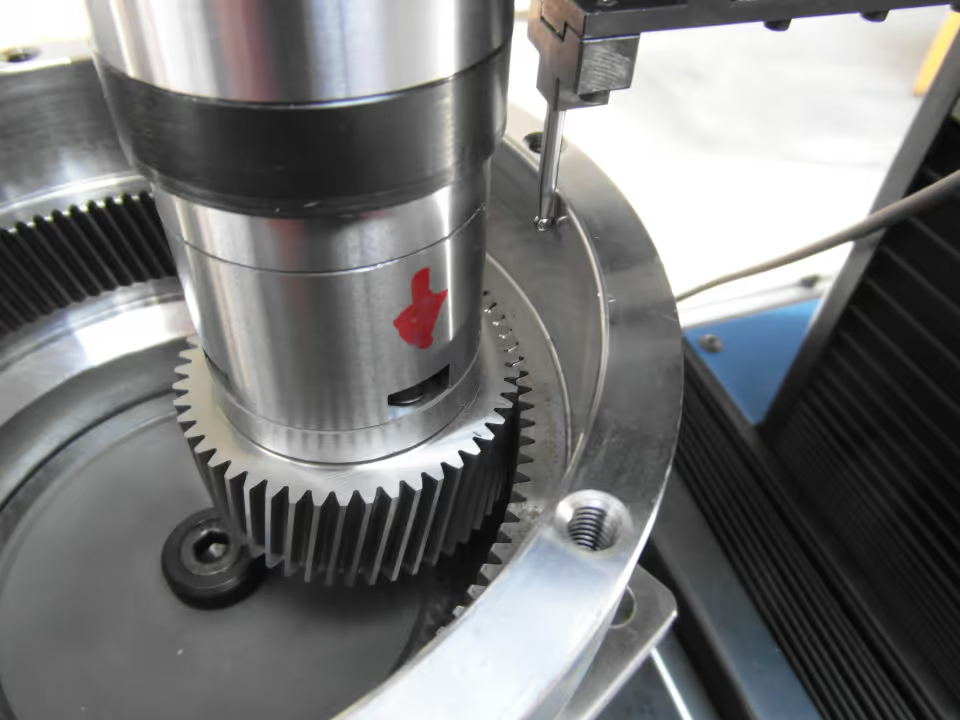

5.3 Advanced Manufacturing Capabilities

• CNC Precision Machining – high accuracy in gear cutting.

• Gear Grinding & Honing – superior surface finish and accuracy.

• Heat Treatment – processes such as carburizing, nitriding, and induction hardening.

5.4 Surface Treatments & Coatings

Chrome plating, nitriding, and custom coatings enhance wear resistance and lifespan.

5.5 Quality Assurance

Our quality process includes CMM gear inspection, hardness testing, surface roughness analysis, and ISO/TS certifications.

Learn more about our Quality Control.

6. Applications of Custom Internal Gears

6.1 Automotive Industry:

Used in transmission systems.

6.2 Mechanical Engineering:

Employed in automation systems and robotic applications.

6.3 Aerospace:

Utilized in flight control systems and propulsion mechanisms.

6.4 Energy Sector:

Incorporated in wind turbines and hydroelectric generators.

6.5 Agricultural Machinery:

Applied in tractors and harvesting equipment.

Explore our Customized Precision Gears.

7. Case Studies

7.1 Automotive Transmission Upgrade

PairGears designed lightweight internal gears for an EV manufacturer, reducing gearbox noise by 15% while maintaining torque density.

7.2 Industrial Robotics

Our gears enabled smoother, high-precision motion in robotic joints, enhancing repeatability by 20% compared to standard gears.

7.3 Agricultural Machinery

For a global tractor brand, PairGears supplied hardened internal gears that extended service life by 30% in heavy-load conditions.

8. FAQ

Q1: What is the minimum order quantity for custom internal gears?

A1: The minimum order quantity depends on the specific product specifications. Please contact our sales team for detailed information.

Q2: How long is the lead time for custom internal gears?

A2: Lead time varies based on the order size and complexity. Typically, we complete orders within 30-45 business days after confirmation.

Q3: What material options are available for custom internal gears?

A3: We offer a range of material options including carbon steel, stainless steel, brass, and others, depending on your application needs.

Q4: Can you provide samples?

A4: Yes, we can provide samples based on your requirements, though a nominal fee may apply.

Q5: How do you ensure product quality?

A5: We adhere to strict testing processes and quality control standards, ensuring that every batch meets the highest industry standards.

Q6: What if I have special customization requirements?

A6: We are happy to accommodate special customization requests and will work with you to develop tailored solutions.

9. Start Your Custom Gear Project with PairGears

Custom internal gears are crucial for achieving efficiency, reliability, and durability in today’s demanding industries. By working with PairGears — a trusted internal gear supplier with decades of expertise, advanced equipment, and ISO-certified processes — OEMs gain a partner that ensures precision at every stage of production. Contact us today to start your project.

Should you have any questions or require further assistance, please do not hesitate to contact our engineer: ben@pairgears.com.