Bevel Gears: Four Common Types, Uses, and Selection Notes

- Share

- publisher

- Jessica

- Issue Time

- Oct 30,2025

Summary

A factory guide to 4 bevel gear types and how to specify material, heat treat, inspection, and supplier selection for repeatable performance.

1. Introduction

Right-angle power transmission looks simple on a drawing. In production, most issues come from a few preventable gaps: the wrong bevel type for the duty cycle, unclear mounting-distance/backlash targets, or weak feedback between machining, heat treatment, and inspection.

This guide summarizes the four common bevel gear types—straight, spiral, hypoid, and zerol—and the checks we use at PairGears to make custom gearsets assemble-ready and repeatable in batch production.

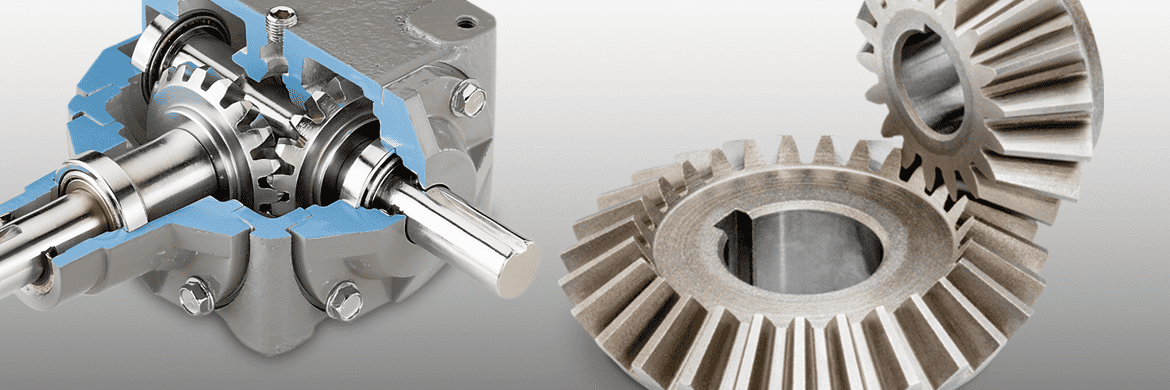

2. What is a bevel gear?

A bevel gear is a conical-tooth gear used to transmit torque between intersecting (or nearly intersecting) shafts—most commonly at 90°.

3. Why bevel gears matter in real machines

The bevel type sets the contact behavior.

Tooth geometry changes contact ratio, sliding, and sensitivity to mounting errors—affecting efficiency, heat generation, and load capacity.Your specification controls distortion and service life.

Material grade, case depth, hardening method, and finishing determine how predictable the gear remains after heat treatment and under long-term load.A bevel gearset is part of a system.

Housing stiffness, bearing preload, lubrication, and assembly tolerances decide whether the designed contact pattern survives real operation.4. Four bevel gear types at a glance

| Type | Tooth form & mesh behavior | Typical applications | Practical notes |

| straight bevel gears | Straight teeth; abrupt engagement and lower contact ratio. | Low-to-medium speed angle drives, simple reducers. | Cost-effective, but more sensitive to shock load and misalignment; best with limited speed and a stiff housing. |

| Curved teeth; smoother engagement and higher contact ratio. | Differentials, transfer cases, compact right-angle reducers. | Needs accurate mounting distance and pattern control; common choice for higher load sharing and compact torque. | |

| Hypoid Bevel Gears | Spiral-like teeth with shaft offset; higher sliding on the flank. | Automotive differentials and offset packaging layouts. | Requires correct lubricant and flank finish; strong for packaging, but the spec must match the duty cycle. |

Zerol Bevel Gears | Curved teeth with near-zero spiral angle; between straight and spiral. | Angle drives needing smoother meshing without strong spiral thrust. | A practical compromise, but still requires contact pattern control and accurate setup. |

Selection is not only about torque. It also affects axial thrust, bearing load, and lubrication risk. For example, hypoid gears typically have more sliding, so oil choice and flank finish become more important.

Spiral and zerol designs generally run smoother than straight bevel gears, but they demand tighter mounting-distance control. If the housing is flexible or assembly variation is large, specify the setup targets and inspection method early to avoid repeated pattern chasing.

5. Who uses custom bevel gears?

Custom bevel gears are commonly used in machinery that needs reliable right-angle power transfer, especially in the following sectors:

● Heavy-duty truck: auxiliary drives, PTO interfaces, differential-related gearsets

● Construction equipment: swing drives, pump drives, compact right-angle reducers

● Electric vehicle: compact drive modules, e-axle reducers, gear units with angle transmission

6. Features that drive repeatability

These control points decide fit, contact pattern stability, and batch-to-batch consistency.

| Feature | What we control in manufacturing | What you receive |

| Geometry + micro-geometry | Mounting distance target, backlash window, pattern tuning, lead/crown corrections, runout control on datums. | Stable contact pattern, consistent backlash, and fewer build-time shimming loops. |

| Material route | Carburizing or through-hardening steels selected for torque, shock load, and distortion risk. | A material choice aligned to duty cycle, with traceable heat/lot information. |

| Heat treatment strategy | Case depth, hardness profile, quench/temper control, and verification to limit scatter. | Target hardness and effective case depth with improved predictability and durability. |

Finishing method | Cutting route plus grinding or lapping/honing when needed to recover geometry and refine flank finish. | Mesh behavior and surface finish matched to speed and lubrication. |

Fixturing + datums | Cutting route plus grinding or lapping/honing when needed to recover geometry and refine flank finish. | Better assembly alignment and less rework from inconsistent references. |

Inspection plan | In-process checks plus final verification: pattern, measurement, runout, hardness, case depth. | Reports that support approval (FAI packs when needed), not just pass/fail. |

7. Benefits you can specify and verify

| Benefit | Practical impact | How it is verified |

Smoother running | More stable contact and lower heat in continuous operation. | Pattern + backlash confirmation, runout checks, and (when needed) flank roughness. |

Longer wear life | Better resistance to pitting and scuffing under real loads. | Hardness profile, effective case depth, material certificates, optional metallography. |

Higher load capacity | Improved load sharing and lower tooth-root risk at peak torque. | Geometry confirmation, micro-geometry records, heat-treatment validation. |

Fewer assembly surprises | Less time spent chasing pattern during build and service. | Defined mounting distance/backlash, matched pairs, setup notes. |

| Faster ramp-up | Shorter iteration loop from sample to stable batches. | DFM summary, sample approval records, defined control plan. |

8. How to choose a bevel gear supplier

A bevel gear supplier is not just a machine shop. You are buying a controlled process that must reproduce the same contact pattern and datums over time.

● Ask for the inspection method and deliverables (pattern records, measurement, hardness/case depth), not only a claimed gear grade.

● Confirm heat-treatment control and the distortion plan—especially whether finishing is planned when tolerances are tight.

● Verify assembly references: mounting distance, backlash window, and whether matched pairs/sets and setup notes are provided.

● Check experience with your type: spiral, hypoid, and zerol usually demand tighter setup and more pattern control than straight bevel.

● Request evidence of repeatability: past batch records, a control plan, and a clear prototype-to-batch ramp process.

9. Common Documentation and Verification

Bevel gears are often purchased with supporting documentation that helps verify repeatability. Typical items include material certificates, heat-treat records, dimensional inspection reports, and—when required—first-article submissions.

When contact pattern checks are used, the setup condition (mounting distance, backlash, bearing preload) should be recorded so results are comparable across inspections.

Where formal gear measurement is requested, reports may summarize tooth geometry deviations (such as profile and lead trends) and reference a defined standard or internal acceptance plan. The goal is to make results comparable across suppliers, batches, and inspection stations.

Common deliverables may include:

● Material certificate and traceability (heat number / batch records)

● Heat treatment report (hardness profile, case depth or nitrided layer)

● Dimensional inspection report for critical datums and runout

● Gear measurement or flank evaluation summary (method and acceptance criteria defined by project)

● Contact pattern reference (with setup condition documented)

10. FAQ

Q: Are Hypoid Bevel Gears Always Better Than Spiral Bevel Gears?

A: Not always. Hypoid bevel gears offer packaging advantages and can carry high torque, but they introduce more sliding and therefore depend heavily on lubrication and surface condition. If shaft offset is not required, spiral bevel gears can be simpler to specify and validate.

Q: When Would A Straight Bevel Gear Be A Reasonable Choice?

A: Straight bevel gears can be suitable for moderate speeds and loads, especially in simpler right-angle drives. They are often selected when manufacturability and controlled assembly are priorities.

Q: What Is The Point Of Zerol Bevel Gears If Spiral Bevel Exists?

A: Zerol gears use curved teeth with a near-zero mean spiral angle. This can help balance manufacturability and load behavior in some designs, while keeping axial forces more similar to straight bevel arrangements.

Q: What Information Is Most Useful For Quoting Or Reviewing A Bevel Gear Set?

A: Beyond the drawing, duty cycle details matter: torque range, speed, direction changes, lubrication type, expected life, and mounting constraints. These inputs help evaluate whether geometry and heat treatment targets are appropriate.

Q: How Do Buyers Reduce The Risk Of Fit Or Pattern Issues During Installation?

A: By defining assembly targets early—mounting distance, backlash, and bearing preload—and verifying critical datums and runout on the gear and mating parts. A repeatable setup method makes contact pattern checks comparable across batches.

11.Conclusion

Custom bevel gears succeed when selection and specifications are made early enough to prevent downstream surprises. Choose the right type, define mounting distance and backlash targets, and align material, heat treatment, finishing, and inspection with the real duty cycle.

Send your drawing (or a sample) with load/speed range and lubrication details. PairGears can review manufacturability, recommend a bevel type, and deliver matched gearsets with inspection data your team can trust.